Three Engineering professors have received funding under the federal Automotive Sector Partnership program, for an energy storage system for cars that will reduce start-up emissions, and for a more fuel-efficient vehicle transmission system.

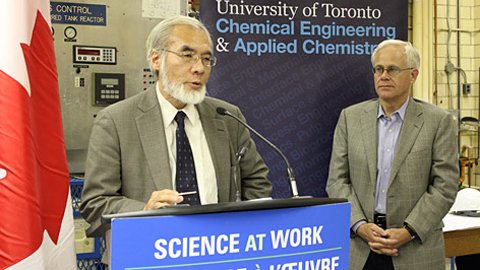

Professors Masahiro Kawaji and Honghi Tran of Chemical Engineering & Applied Chemistry will receive $234,000 for their research, in partnership with the Thermal Products Group of Dana Canada Corporation, which will provide an additional $33,000 of funding.

Professor Jean Zu, Chair of Mechanical & Industrial Engineering, will receive a grant of $284,000 to develop innovative timing belts which promises to boost vehicle efficiency by as much as 15 percent. Professor Zu’s industry partner is the Toronto-based design and engineering company Vicicog.

“This is wonderful news for the Faculty,” said Professor Stewart Aitchison (ECE), Vice-Dean, Research for the Faculty of Applied Science & Engineering. “The funding will help us build on successful partnerships in the automotive area.”

On October 15th the Honourable Tony Clement, Minister of Industry for Canada, announced a total of four projects under the Automotive Partnership Canada program. The projects will increase research and design in the automotive sector across several promising fields, including electric vehicles and advancing software in the automotive sector. Three other universities—McMaster, Waterloo and British Columbia—were also awarded funding.

“We all know that the automotive industry is critical for the health and wealth of Canada,” said Peter Lewis, Associate Vice-President, Research for the University of Toronto, at the announcement of the U of T grants on October 15th. “It is absolutely essential that this sector holds and continues to strengthen its position … How do we achieve this? Through innovation, cooperation, partnership, the exchange of views and sharing of ideas.”

Professors Kawaji and Tran, in partnership with Dana Canada Corporation, have begun working on their thermal energy storage study in order to better understand the mechanics of reactor design that will enable viable commercial applications. Increased fuel economy means more energy management in automotive design. This requires waste energy storage and reuse, which will contribute to reduced start-up emissions and less time to start a cold engine and power train (through active warming of the power train oils). This technology will likely be used the most for hybrid and electric vehicles.

The research will determine an appropriate metal oxide-hydroxide reactor to efficiently store and release internal combustion engine waste exhaust energy; metal oxide-hydroxide heat storage and retrieval is a promising technology but lacking sufficient reactor-mechanics understanding at present for commercial applications. Latent heat storage, based on a phase change material, will also be investigated to identify the relative advantages of chemical and latent heat storage systems.

Professor Zu’s work with industry partner Vicicog will create a new transmission system that promises to boost vehicle fuel efficiency by as much as 15 per cent.

In order to improve efficiency, current automotive transmission technology often necessitates engine design compromises. In particular, existing manual and automatic transmissions, because they have too few gears, require an engine that sacrifices efficiency and peak horsepower. Researchers have developed a belt and pulley system that is much more efficient, using leading-edge belt and computer control technologies that can shift under load, handle high torque and provides a greater range of gears. The researchers hope to produce a working prototype designed in conjunction with the automotive industry. With successful completion, Vicicog will be well positioned to bring the highly disruptive, unique transmission product to market.

Automotive Partnership Canada (APC) is a five-year $145-million initiative to support significant, collaborative, industry-driven research and development that benefits the Canadian automotive sector. APC receives funding from the Natural Sciences and Engineering Research Council ($85 million); National Research Council ($30 million); Canada Foundation for Innovation ($15 million); Social Sciences and Humanities Research Council ($5 million), and Canada Excellence Research Chair Program ($10 million).

Professor Jean Zu has served as Chair of the Department of Mechanical & Industrial Engineering since July, 2009. She previously served as Associate Chair of Research from 2008 to 2009. Her research has been focused on mechanical vibrations and dynamics, where she has successfully collaborated with different companies on research projects for automotive applications.

Professor Masahiro Kawaji (EngSci BASc 7T8) has taught in the Department of Chemical Engineering & Applied Chemistry since 1986. His research areas include multiphase flow and phase change heat transfer, transport phenomena, microfluidics and micro-heat pipes. He is a Fellow of both the Chemical Institute of Canada and the American Society of Mechanical Engineers.

Professor Honghi Tran has taught and researched in the Chemical Engineering & Applied Chemistry Department since 1982, when he received his PhD from the department, and serves as the Director of ChemE’s Pulp & Paper Centre. Professor Tran is also a technical consultant to kraft pulp mills. His research interests are in fouling and corrosion in recovery boilers and chemical recovery processes.

Follow the links to read an article on the research grants in the Toronto Sun, and the Government of Canada press release on Marketwire.