Three U of T Engineering researchers have partnered with leading companies to strengthen technological innovation and enhance sustainability in pulp & paper, manufacturing and natural resources — sectors that are all key drivers of the Canadian economy.

The NSERC Industrial Research Chairs (IRCs) provide funding over five years to support academic-industry collaborations on both fundamental and applied research that is of commercial interest. The latest appointments bring the total number of IRCs at U of T Engineering to 10, joining existing collaborations in areas ranging from drinking water treatment to nuclear power systems.

“These industrial research chairs reflect our ability to attract world-leading research talent and to build strong relationships with external partners in a wide variety of fields,” said Ramin Farnood, Vice-Dean, Research at U of T Engineering. “The new discoveries and innovations that they create will improve the competitiveness of their respective sectors and create value for Canadians.”

The three new Industrial Research Chairs are:

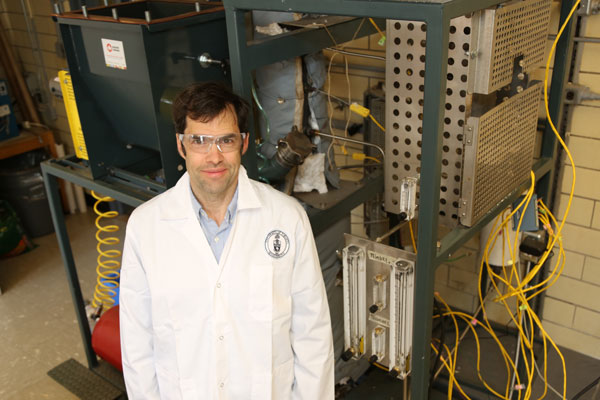

Professor Nikolai DeMartini (ChemE) — NSERC Industrial Research Chair in the Role and Fate of Inorganics in the Industrial Processing of Woody Biomass

The raw material of the pulp and paper industry is wood. But mixed in with this wood are various inorganic chemicals contaminants such as salts and metals, which are commonly found in forest soil and make their way into the growing trees. The presence of these contaminants is not just a nuisance — they can actually damage process equipment, reduce overall efficiency and create environmental headaches for the surrounding community.

Professor DeMartini has spent years studying the chemical process that take place inside pulp and paper plants. He has developed strategies for new industrial processes that can effectively deal with these inorganic components. The results could add value to existing operations and reduce unwanted emissions, leading to benefits both for the companies and surrounding communities.

Partners on the project include FPInnovations, a not-for-profit organization dedicated to improving the competitiveness of the Canadian forest sector, as well as a number of major pulp and paper producers.

Professor Chul Park (MIE) — Senior NSERC/NanoXplore Industrial Research Chair in Multifunctional Graphene-based Nanocomposites and Foams

Made from a single layer of carbon atoms, graphene is a material with the potential to revolutionize certain areas of manufacturing. In addition to having very high structural strength for its size, it is also highly conductive of both electricity and heat. If added to conventional plastics and foams, it could lead to new composite materials with properties that current materials don’t have.Professor Chul Park (MIE) has partnered with NanoXplore, a company that manufactures graphene nanoplatelets. Together, the team is working to make composites of graphene and foamed plastic that can conduct heat away from sensitive electronic devices or provide shielding from electromagnetic interference. Such novel materials would be useful in sensors, smartphones and other portable electronic equipment.

Professor Giovanni Grasselli (CivMin) — NSERC/Foundation CMG Industrial Research Chair in Fundamental Rock Physics and Rock Mechanics

Whether they are digging subway tunnels or drilling for natural resources, companies need to understand and predict how rocks will react to various stresses. Computer models address this problem, but in the past many of these models could predict only whether or not a rock would break — they provided little information about the path the fracture would take, or how that fracture would affect subsequent drilling efforts.

Professor Giovanni Grasselli (CivMin) and his team are taking a new approach. They are working with computer models that combine both the continuous and discontinuous aspects of the fracturing process, providing a more accurate simulation. They have also created pressure vessels that can be used to subject rocks sampled from an industrial site to controlled stresses in the lab. These vessels are transparent to x-rays, which enables the team to monitor how the fractures progress through the rock sample in real time. Detailed measurements from these laboratory experiments are used to inform the computer models, further enhancing their accuracy.

Partners on the project include EnergiSimulation, a not-for-profit organization dedicated to creating a more sustainable energy future through simulation research, as well as two software companies: Computer Modelling Group, Ltd. and Geomechanica, Inc. Geomechanica was founded by U of T graduates, including three alumni of Grasselli’s lab, two of whom were awarded prizes by the International Society for Rock Mechanics and Rock Engineering for the top PhD thesis in the world in 2015 and 2017.