Imagine a machine that makes layered, substantial patches of engineered tissue – tissue that could be used as grafts for burn victims or vascular patches. If this sounds like science fiction, researchers at the University of Toronto say it’s a growing possibility.

A team led by two U of T Engineering professors has invented a new device that may allow for the uniform, large-scale engineering of tissue. Associate Professor Axel Guenther of the Department of Mechanical & Industrial Engineering, cross-appointed to the Institute of Biomaterials & Biomedical Engineering (IBBME), and Associate Professor Milica Radisic, core professor at IBBME and the Department of Chemical Engineering & Applied Chemistry, developed the device with a team included graduate students Lian Leng, Boyang Zhang, and Arianna McAllister.

“There’s a lot of interest in soft materials, particularly biomaterials,” explained Professor Guenther, “but until now no one has demonstrated a simple and scalable one-step process to go from microns to centimeters.”

The invention, presented in a cover article for the journal Advanced Materials this month, is currently being commercialized by MaRS Innovations in collaboration with the Innovations and Partnerships Office (IPO) of the University of Toronto, through which Professors Radisic and Guenther’s labs have filed two patents on the device.

But how exactly does a machine grow a large patch of functional tissue?

Scientists manipulate biomaterials into the micro-device through several channels. The biomaterials are then mixed, causing a chemical reaction that forms a “mosaic hydrogel” – a sheet-like substance compatible with the growth of cells into living tissues, into which different types of cells can be seeded in very precise and controlled placements.

The current methods for tissue engineering relies on scaffolding, in which cells are seeded onto an artificial structure capable of supporting three-dimensional tissue formation. However, that method provides little control over where the cells settle. The U of T method allows cells planted onto the mosaic hydrogel sheets to be precisely incorporated into the mosaic hydrogel sheet just at the time it’s being created – generating the perfect conditions for cells to grow.

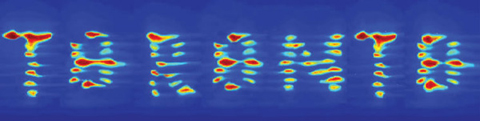

The placement of the cells is so precise, in fact, that scientists can spell words (such as “Toronto,” shown above) and can accurately mimic the natural placement of cells in living tissues. By collecting these sheets around a drum, the machine is able to collect layers of cells in thicknesses made to measure: in essence, three dimensional, functional tissues.

In tissue engineering, cell placement is everything: something that the new invention delivers. “The cells are able to stretch and connect with each other, which is very important for ultimately obtaining functional tissues,” Guenther states.

The resulting tissues are remarkably stable, explained Leng, lead author on the project and a third-year PhD Candidate in Mechanical & Industrial Engineering. “In this case, when we put the cells in the right places, we create cellular organization quite naturally.”

So what’s the next step?

“With the help of biomaterials experts and clinical collaborators, my laboratory is currently pursuing different applications of the technology – different tissues,” said Professor Guenther. The technology may provide the means to create three-dimensional cell cultures for the development of therapeutic drugs, for instance. “But one of my dreams is to one day engineer a vascularized leaf – perhaps a maple leaf,” he joked.

Currently, the two U of T labs are also collaborating with a burn unit at Sunnybrook Hospital. “At some point [the machine] could allow dermal [skin] grafts to be prepared that perhaps will be less expensive and more efficient,” stated Professor Guenther.

Learn more about it in the winter 2013 issue of U of T Magazine.