The Centre for Research and Applications in Fluidic Technologies (CRAFT) has opened a new and expanded Tissue Foundry at the University of Toronto. The new facility builds CRAFT’s fabrication capacity following the launch of its Device Foundry in 2021.

CRAFT, a U of T Institutional Strategic Initiative and collaborative research centre formed in partnership with the National Research Council of Canada (NRC), will operate the open research facility at U of T’s Mechanical Engineering Building.

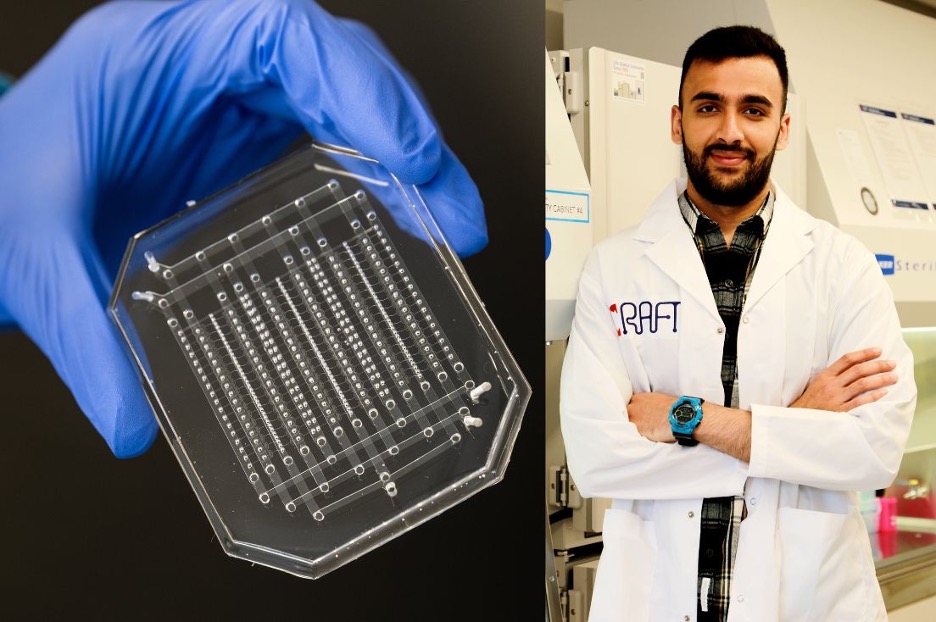

The Tissue Foundry offers a wide range of instruments to allow microfluidics researchers to complete the preclinical assessment of their devices, culture and image tissues for their research, and print physiologically relevant 3D structures using biomaterials and cells. NRC Technical Officers at CRAFT support the Foundry and train students who would like to use the equipment for their research projects.

“The expanded Tissue Foundry provides new equipment and expert technical staff to advance research in new and exciting directions,” says Professor Axel Guenther (MIE, BME), CRAFT co-director.

“CRAFT makes every effort to ensure affordable and efficient access to state-of-the-art equipment and expert training for all interested research labs and their trainees. We are grateful to our CRAFT colleagues leading infrastructure initiatives and the support received from the Canada Foundation of Innovation, the Natural Sciences and Engineering Research Council of Canada and the NRC.”

The new instruments include a biomechanical tester for obtaining mechanical properties of biological materials and a light sheet microscope for enhanced optical sectioning and 3D biological imaging. These instruments were contributed by the Ontario-Québec Center for Organ-on-a-Chip Engineering, led by Professor Milica Radisic (BME, ChemE), CRAFT co-lead.

“This equipment will enable organ-on-chip researchers to perform increasingly automated drug screens and at a higher-throughput on 10+ human tissue models at a time, significantly accelerating drug discovery and development efforts,” says Radisic.

The increased capacity and new equipment will help to fuel more bioengineering innovations at the University, including those emanating from the six projects funded by CRAFT in 2021.

Sushant Singh (MIE), a second-year PhD candidate in the Guenther Lab, is creating novel bioinks that are compatible with the lab’s handheld 3D skin printer to treat full-thickness skin burns.

“The facilities at CRAFT are integral to my research,” says Singh. “The Device Foundry allows us to develop and fabricate microfluidic devices that can produce large quantities of bioink needed to optimize bioprinting conditions. And the Tissue Foundry provides the equipment necessary to culture bioprinted tissues and later analyze them with a variety of instruments, such as the atomic force microscope, confocal microscope and rheometer.”

Singh hopes to commercialize his research by spinning out a company, which is an important milestone before the 3D skin printer and new bioink can be used widely in hospitals as a treatment for large skin burns. CRAFT facilities and resources are helping Singh work towards both milestones.