U of T Engineering graduate student launches market-ready solution for sustainable transportation

New advanced material formulation improves the durability and efficiency of battery cases for EVs, as well as traditional internal combustion vehicles

ECE’s new Keysight Electronics Laboratory will empower future innovators

Hands-on educational facility designed to enable undergraduates to gain practical experience through collaboration with researchers on long-term projects

U of T and BASF partner on self-driving labs to advance agriculture, medicine and more

Partnership agreement leverages AI and automation to design new chemical products with applications in crop protection, industrial coatings and drug delivery

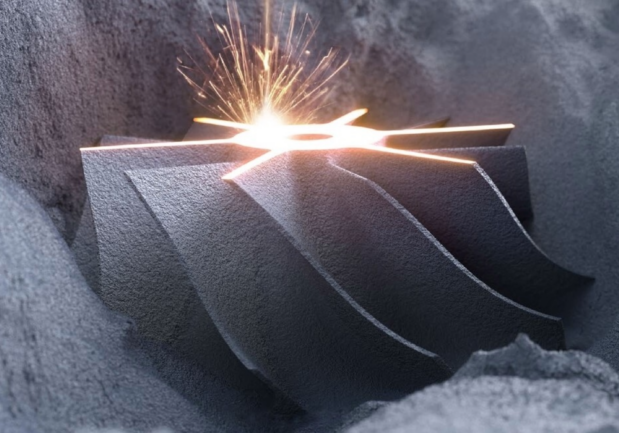

New machine learning framework enhances precision and efficiency in metal 3D printing, advancing sustainable manufacturing

Research led by Professor Yu Zou (MSE) aims to produce higher quality and more reliable metal parts for aerospace, automotive, energy and health-care applications

Strong as steel, light as foam: Machine learning and nano-3D printing produce breakthrough high-performance, nano-architected materials

Research led by Professor Tobin Filleter (MIE) could benefit industries from automotive to aerospace

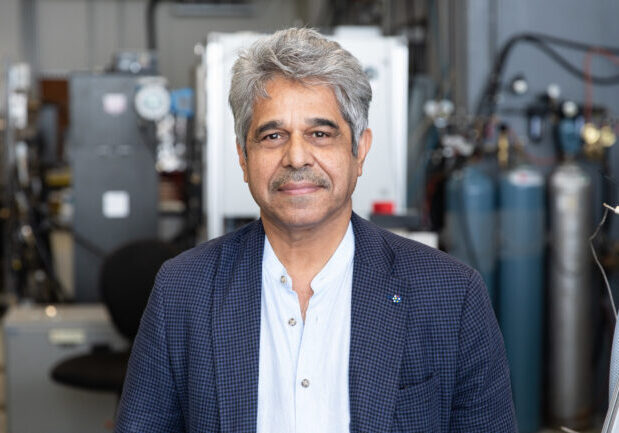

Professor Javad Mostaghimi elected to the U.S. National Academy of Inventors

Mostaghimi recognized for innovation in creating inventions that have made an impact on quality of life, economic development, and the welfare of society