New funding from the Natural Sciences and Engineering Research Council (NSERC) will advance U of T Engineering research in a wide range of areas, from digital infrastructure to advanced manufacturing.

NSERC recently announced five Strategic Partnership Grants to help U of T engineers address complex global challenges, including improved methods for sharing data from consumer devices and analytics that enhance quality control in factories.

In total, the program invested more than $2.6 million in U of T Engineering and more than $3.8 million across the entire University.

“These projects are illustrative of the way that our professors and students are creating tomorrow’s technologies today,” said Ramin Farnood, Vice-Dean, Research at U of T Engineering. “Together with our partners, we are leveraging engineering innovation to build a more prosperous and sustainable world.”

The five principal investigators and their associated projects are:

Peter Herman (ECE) — Photonic circuits manufacturing

Photonic circuits are widely used in the fibre optic infrastructure that underpins our modern Internet. This project will focus on new methods of manufacturing photonic circuits that can integrate inside of optical fibre by using laser-based technologies that are similar to 3D printers. By combining the speed and precision of lasers with the customization available to 3D printers, this emerging technology will lead to new fibre optic tools serving widely from high speed data centres to minimally invasive surgical tools.

Wai Tung Ng (ECE) and James K. Mills (MIE) — Gallium nitride manufacturing

Gallium nitride (GaN) is a wide bandgap semiconductor material that is well-suited to number of applications, from light-emitting diodes that provide energy-efficient lighting to microwave/radio-frequency power amplifiers. This project will advance technologies for the manufacturing techniques of liquid cooled GaN power modules to meet the stringent performance demands from the power converters in future Electric Vehicles. This project is an international collaboration with Dana Canada, a tier one automotive parts manufacturer and Taiwan Semiconductor Research Institute.

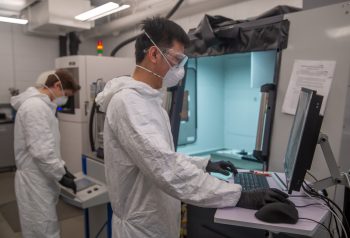

Yu Sun (MIE) — Improving quality control in factories

Maintaining quality control in auto parts factories and other advanced manufacturing operations requires integrating detailed measurement data in real time. This project, by Sun and Professor David Fleet (Computer Science) will leverage new sensor technologies, analytical techniques, as well as industry robot control to attain accurate 3D point clouds of auto parts for quality control. The new tools will enable manufacturers to make faster, better decisions, enhancing customer satisfaction and improving economics across a wide range of processes.

Sean Hum (ECE) — Satellite antennas for IoT and M2M

Hum’s project will focus on bolstering Canada’s network infrastructure. His research group will develop innovative satellite antennas for Internet of Things (IoT) and machine-to-machine (M2M) networks that would otherwise be difficult to serve using non-satellite infrastructures. This work would have applications for connected transportation, smart agriculture, remote monitoring and telematics, where M2M/IoT devices have no nearby non-satellite infrastructure to connect to, and hence, would rely on satellites for coverage.

Erin Bobicki (MSE, ChemE) – Combining CO2 storage with mineral processing

Certain mineral processing wastes have the capacity to store CO2 in mineral form. CO2 also has the potential to be used as a novel reagent to enhance the separation of minerals and stabilize waste materials. This presents an opportunity to both store CO2 captured from flue gases or other industrial sources and enhance the extraction of metals from ores. Depending on the regulatory framework or incentives around CO2 sequestration, these processes could add new revenue streams for mineral processing companies. This project will investigate the potential viability of these new strategies.