Researchers at U of T Engineering, led by Professor Yu Zou (MSE), are leveraging machine learning to improve additive manufacturing, also commonly known as 3D printing.

In a new paper, published in the journal of Additive Manufacturing, the team introduces a new framework they’ve dubbed the Accurate Inverse process optimization framework in laser Directed Energy Deposition (AIDED).

The new AIDED framework optimizes laser 3D printing to enhance the accuracy and robustness of the finished product. This advancement aims to produce higher quality metal parts for industries, such as aerospace, automotive, nuclear and health care, by predicting how the metal will melt and solidify to find optimal printing conditions.

“The wider adoption of directed energy deposition — a major metal 3D printing technology — is currently hindered by the high cost of finding optimal process parameters through trial and error,” says Xiao Shang (MSE PhD candidate), first author of the new study.

“Our framework quickly identifies the optimal process parameters for various applications based on industry needs.”

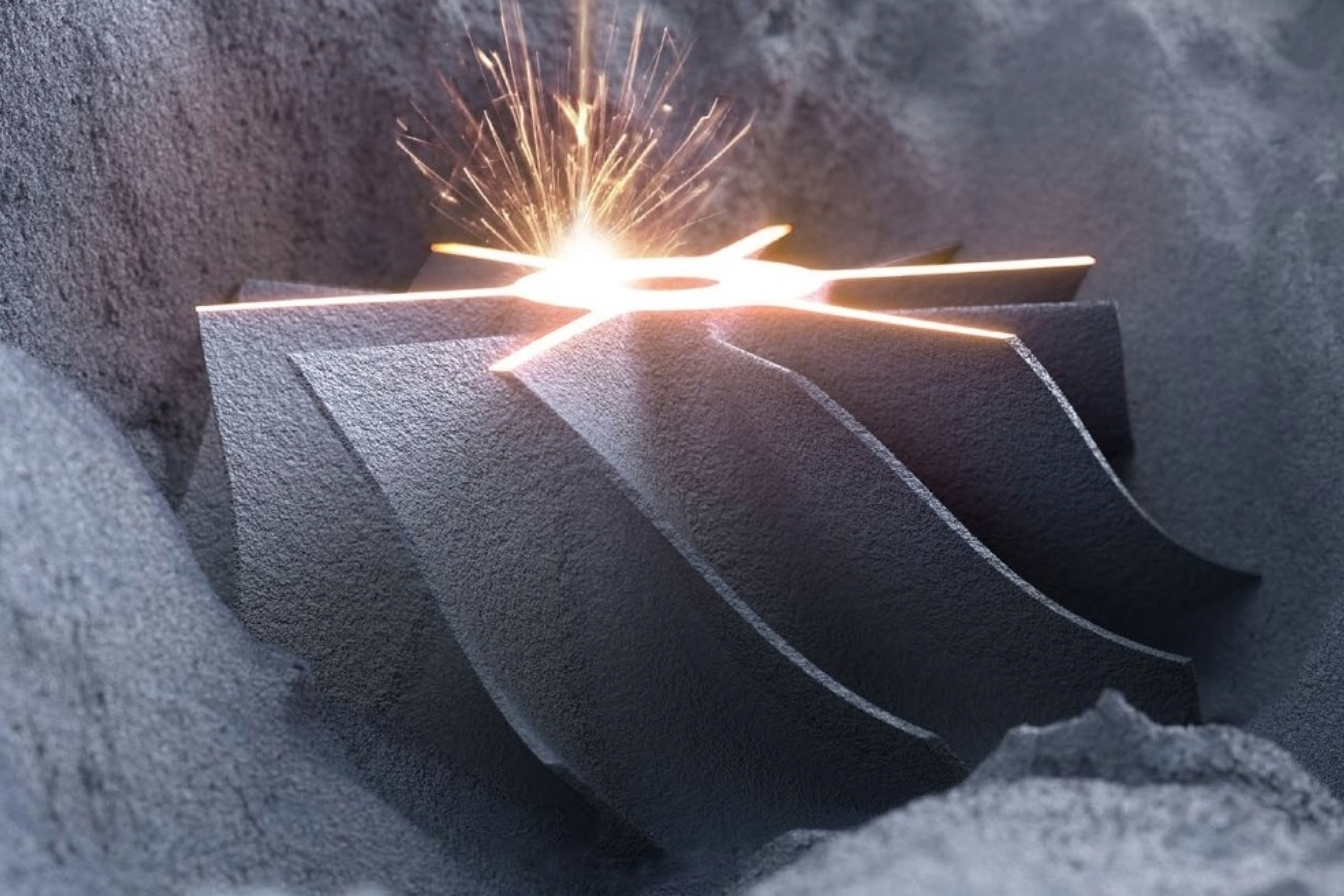

Metal additive manufacturing uses a high-powered laser to selectively fuse fine metallic powder, building parts layer by layer from a precise 3D digital model.

Unlike traditional methods, which involve cutting, casting or machining materials, metal additive manufacturing directly creates complex, highly customized components with minimal material waste.

“One major challenge of 3D metal printing is the speed and precision of the manufacturing process,” says Zou. “Variations in printing conditions can lead to inconsistencies in the quality of the final product, making it difficult to meet industry standards for reliability and safety.

“Another major challenge is determining the optimal settings for printing different materials and parts. Each material — whether it’s titanium for aerospace and medical applications or stainless steel for the nuclear reactors — has unique properties that require specific laser power, scanning speed and temperature conditions. Finding the right combination of these parameters across a vast range of process parameters is a complex and time-consuming task.”

These challenges inspired Zou and his lab group to develop their new framework. AIDED operates in a closed-loop system where a genetic algorithm — a method that mimics natural selection to find optimal solutions — first suggests process parameters combinations, which machine learning models then evaluate for printing quality.

The genetic algorithm checks these predictions for optimality, repeating the process until the best parameters are found.

“We have demonstrated that our framework can identify optimal process parameters from customizable objectives in as little as one hour, and it accurately predicts geometries from process parameters,” says Shang. “It is also versatile and can be used with various materials.”

To develop the framework, the researchers conducted numerous experiments to collect their vast datasets. This essential but time-consuming challenge ensured that the datasets covered a wide range of process parameters.

Looking ahead, the team is working to develop an enhanced autonomous, or self-driving, additive manufacturing system that operates with minimal human intervention, similar to how autonomous vehicles drive themselves, says Zou.

“By combining cutting-edge additive manufacturing methods with artificial intelligence, we aim to create a novel closed loop controlled self-driving laser system,” he says.

“This system will be capable of sensing potential defects in real-time, predicting issues before they occur, and automatically adjusting processing parameters to ensure high-quality production. It will be versatile enough to work with different materials and part geometries, making it a game-changer for manufacturing industries.”

In the meantime, the researchers hope AIDED will transform process optimization in industries that use metal 3D printing.

“Industries such as aerospace, biomedical, automotive, nuclear and more would welcome such a low-cost yet accurate solution to facilitate their transition from traditional manufacturing to 3D printing,” says Shang.

“By the year 2030, additive manufacturing is expected to reshape manufacturing across multiple high-precision industries,” adds Zou. “The ability to adaptively correct defects and optimize parameters will accelerate its adoption.”