A U of T Engineering team is developing a new way to coat minute particles of copper onto the inside of fabrics, such as those used in face masks. The technology could provide an additional layer of safety to help slow the spread of COVID-19.

The goal is to deposit very fine copper particles onto both woven and non-woven fabrics using twin-wire arc (TWA) spray technology. This fabric will then be used in one of the layers of a reusable fabric face mask. It’s anticipated this copper-embedded fabric will not affect filter or flow rate parameters and will be able to irreversibly kill most viral and other pathogens within a few minutes.

By embedding the copper into the fabric, the masks will provide a continuous and proactive fight against the transmission of current and evolving harmful pathogens without altering the physical barrier properties of the masks.

The anti-microbial properties of copper have been observed since ancient times — Egyptian and Babylonian soldiers would place bronze shavings in their wounds to reduce infection and speed up healing. Today, Professor Javad Mostaghimi (MIE) and his team — including co-investigators Professor Mohini Sain (MIE), Dr. Larry Pershin (MIE), Professor James A. Scott (Public Health) and Professor Maurice Ringuette (Cell & Systems Biology) — are exploiting these same anti-microbial properties to develop coatings that safeguard everything from office furniture to personal protective equipment, such as masks.

“If we can harness the anti-microbial properties of copper to improve the effectiveness of reusable face masks we can significantly reduce the spread of COVID-19 and do a better job at protecting both our frontline workers and our community at large,” says Mostaghimi.

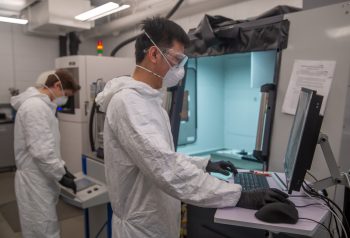

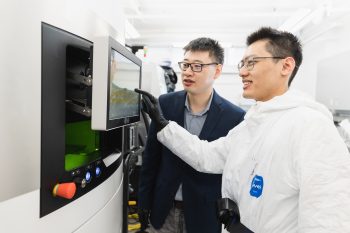

Mostaghimi directs the Centre for Advanced Coating Technologies (CACT), and has studied the impact of copper coatings on healthcare-associated infections for years. He has seen first-hand how copper coatings can be used on high-touch surfaces to help kill bacteria.

In one study, a copper coating was applied to the handles of half the chairs in a Toronto General Hospital waiting room. Over the course of five months they saw that the chairs with copper coatings had a 68 percent reduction of viable bacteria cells per centimetre square.

Current research from other groups shows COVID-19 surviving two to three days on stainless steel and even longer on other surfaces, however it has been demonstrated that the coronavirus particles were inactivated within four hours when exposed to a copper-coated surface at room temperature.

“Traditionally, implementing copper coatings would be very expensive,” Mostaghimi explains. “But our research has developed a method that makes applying copper coatings more economically viable.”

The CACT method is known as twin-wire arc spray. The “wire” part refers to the fact that the raw copper is supplied in the form of copper wire, which is more affordable than copper powders. The spray rates allow for large surfaces to be coated efficiently.

Another advantage is that the TWA method allows for the spray parameters to be controlled so that even heat-sensitive surfaces — such as wood, fabrics and even cardboard — can be coated.

Mostaghimi and his team were awarded an Alliance Grant from the Natural Sciences and Engineering Research Council (NSERC) to explore the possibility applying the TWA method to create copper-embedded fabrics for manufacturing reusable face masks.

For their project titled Copper Embedded Fabrics and Face masks for Rapid, Irreversible Destruction of COVID-19, Mostaghimi and his team are collaborating with Green Nano Technologies Inc. who will produce a pilot set of the copper embedded face masks.

“Using our TWA spray technology, we will be able to produce copper embedded masks at a marginally more expensive cost than N95 surgical face masks,” says Pershin, the Centre Manager at the CACT.

“Additionally, as copper degrades both DNA and RNA genetic material, the masks will have the added benefit of irreversibly inactivating all microbial pathogens, regardless of their mutation rates even after masks were disposed.”

Various copper concentrations will be tested on the fabrics to help determine the optimal parameters for destroying the virus. The copper-embedded fabrics will be tested by Professor Maurice Ringuette of U of T’s Department of Cell & Systems Biology. Ringuette and his team will use the fluid released from virus-infected bacteria when ruptured, called bacteriophage lysates, to simulate the COVID virus on the masks.

The research has potential health and safety benefits that could extend beyond the end of the current pandemic. To have affordable, reusable anti-viral PPE available for healthcare workers could mean a decrease in disease transmission in healthcare facilities and a reduction in healthcare-associated infections.