In 2011, venture capitalist and champion of higher education Seymour Schulich established the Schulich Leader Scholarships. Every year since, U of T has welcomed talented STEM students with a commitment to their community to our program.

This year, Aidan Aird of Markham, Ont. and Andres Lombo from Oakville, Ont. are entering our Engineering Science program. They are both curious, passionate about science and excited to share their enthusiasm with others. Both have started initiatives in their community to encourage kids to get interested in science. Writer Xarissa Thompson spoke to them about what brought them to U of T Engineering.

Andres Lombo (Year 1 EngSci)

What drew you to the University of Toronto?

The most important thing for me is the community. I was in an International Baccalaureate program with 37 other people. I really liked the sense of a close community all working towards the same goal and graduating together.

What brought you to Engineering?

My parents were both engineering professors in Colombia and they encouraged me in whatever ideas I had. For instance, I built a trebuchet out of Lego, using string and a rock from the backyard. We never got to fire it because it was dangerous. My parents’ philosophy is that you either lead society or society leads you. You have to take your curiosity and let it push you into exploring the world. And most times this will lead you into something that will really impact society.

You’re passionate about sharing science with kids. How have you helped to do that?

I founded Voyage Science with friends. There’s a stigma that STEM is for nerdy kids. I first noticed it in the 7th and 8th grade. The excitement for science would die off as people started to just study from textbooks. Science should be open to everyone and I wanted to inspire that. Voyage Science did interactive presentations in the gym, not as a lecture, but by presenting awe-inspiring experiments. We’d come in with lab coats and goggles and they’d know something crazy was going to happen. It really created excitement and I discovered that teaching is one of the best ways to learn.

What do you think of Skule so far?

It’s great. I went full purple at Orientation Week. It truly exceeded my expectations. Mind-blowing would be an understatement. I’ve learned so much about U of T and Engineering traditions. Behind the academics I see a community and a history that make me very happy to study here.

What are your future plans?

I am currently very open to a wide range of interests within engineering. I came to U of T because I really like the academic challenge, I want to dig into the nitty-gritty of every single topic that interests me. And I want to be involved with topics at the leading edge of science.

Aidan Aird (Year 1 EngSci)

Why did you choose U of T?

The Schulich Leaders Scholarship was definitely a big part of it, but also the prestige of the engineering program. It’s consistently one of the top ranked, not just in Canada, but globally. It also means I’ll be able to stay close to home and keep my connections with the charitable programs I’ve been involved with, so it was a win-win-win all around.

What got you into Engineering?

My parents really encouraged and supported me in exploring whatever I was interested in. As kids, my sister and I spent a lot of time at the zoo, the ROM and the Ontario Science Centre, which really sparked my interest in science and engineering. It led me to be interested in science fairs, and in grade seven I was fortunate to advance to my first of four national science fairs. The first year I built a three-meter totally functional wind tunnel, and then I started to focus on developing inventions to help the people living in the developing world.

You’re very interested in encouraging others to explore STEM. How have you done that?

After returning from my first science fair I started an organization called Developing Innovations to promote young STEM innovators and we’ve featured over 70 STEM students so far. A couple of years ago my sister Keeley and I started STEM Kids Rock, a science outreach program for kids. We have an extensive collection of prehistoric fossils, exotic insects and unique minerals that we take to community centres, museums, libraries, schools, and community events. We have over 50 student volunteers that have helped inspire over 100,000 kids. By the end of this year, we should hit our goal of 150 STEM outreach events since we started, which will coordinate with Canada 150.

You have also worked a lot in philanthropy.

My parents and grandparents were a big influence on me and taught me the importance of giving back. I organized my first big event when I was about eight, a hockey food drive. I’m very passionate about ending youth homelessness and have even slept on the streets a few times during the winter, in order to get a better idea what it may be like to be a homeless youth and to help raise funds and awareness. It was tough. It was really eye-opening to think that kids do this every single night and then still go to school. I struggled to do it one night a year.

What are your future plans?

I’m in the engineering science program, which will allow me to continue exploring the things I love. Ultimately my goal is to be an entrepreneur. I love creating and inventing, and this would tie together all my passions. I look up to people like Elon Musk or Bill Gates, who really give back through philanthropy, and I aspire to one day be like them.

Fujitsu Laboratories Ltd. is setting up a new research and development centre in Toronto to create the next breakthroughs in quantum-inspired computing as part of a new partnership with the University of Toronto.

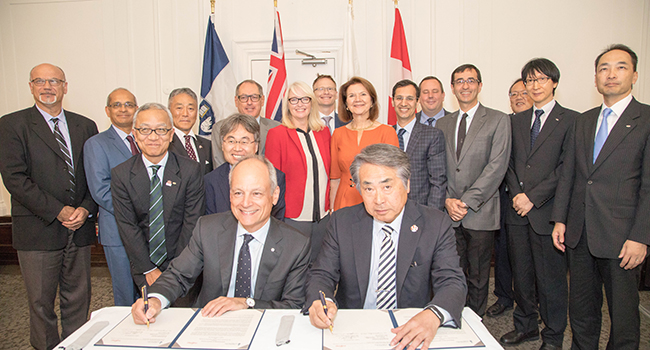

“In partnering with the University of Toronto, you have come to the right place,” U of T President Meric Gertler told a Japanese delegation shortly before signing a memorandum of understanding with Shigeru Sasaki, CEO and Representative Director of Fujitsu Laboratories Ltd., earlier this month. “We look forward to the great things we will accomplish together in the years to come.”

This marks the first R&D centre opened in Canada by Fujitsu Labs, a major engine of research and development in the world’s leading innovation clusters such as Silicon Valley, London and Shanghai.

A separate, independent centre for research collaboration will also be established at U of T, led by Ali Sheikholeslami, a professor in the Edward S. Rogers Sr. Department of Electrical & Computer Engineering.

Fujitsu Labs is the latest tech multinational to locate in Toronto, drawn by the city’s burgeoning global innovation reputation in artificial intelligence and health care — growth areas that have happened because of ongoing cutting-edge research conducted at U of T and its nine affiliated hospitals.

The partnership between Canada’s leading research university and Fujitsu Labs has been almost 20 years in the making. This agreement marks an exciting new chapter in this collaboration, which Sasaki called the “best.”

“We feel there is great importance in strengthening our ties with the University of Toronto, whose exceptionally talented people have achieved preeminent results in research not only in the field of computing but also health care, finance and other fields,” he told the audience.

Guests from all three levels of government including Toronto Mayor John Tory were on hand at the event, which fell into place after the president and Professor Ted Sargent (ECE), U of T’s vice-president of international, visited the company in Tokyo last fall.

To date, the relationship between U of T and Fujitsu Labs has led to 10 patents, the publication of more than 30 joint research papers and $7.5 million CAD in direct funding and in-kind contributions for research.

And it all started with a six-week internship by Sheikholeslami at the company’s headquarters in 1998 where he was finally able to complete the modeling work he researched on while a PhD student at U of T.

“I would’ve never imagined at that time – 20 years later we’d be sitting here talking about all of this,” he said with a laugh. “I’m very happy to have Fujitsu Labs here now finally.”

Sheikholeslami and his long-time collaborator at Fujitsu Labs, Hirotaka Tamura, have collaborated on advances in non-volatile memory technology (used in contactless smart cards), high-speed signalling and the creation of the world’s first digital annealer — an important leap forward in quantum-inspired computing.

The company plans to work with U of T to “accelerate the practical use of quantum computing technologies“ that can reach beyond the limitations of today’s supercomputers to tackle complex global challenges that involve massive amounts of data and various elements that complicate calculations.

Interest in quantum computing and how to find a way to apply it in business is why U of T’s Creative Destruction Lab launched a new quantum machine learning stream for startups earlier this month. The roughly 25 startups involved in the program have access to the world’s only commercially available quantum computers, also known as quantum annealers, built by Vancouver’s D-Wave Systems.

To date, only a handful of U.S.-based organizations have had the tens of millions needed to invest in D-Wave’s bleeding edge technology. They include Google, Lockheed Martin and the Los Alamos National Laboratory.

Sheikholeslami said he’s interested in speaking with CDL to see how they, too, can be involved in this stream. He and Fujitsu Labs are also interested in working with U of T’s globally renowned machine learning experts to use their technology to speed up their AI algorithms.

What is a Digital Annealer and how does it work?

Annealing, a term borrowed from material science, means to find an optimum solution, i.e. one with the least “energy.” In the quantum world, this means finding the best needle in a pile of millions and even billions of bits of information — and doing it quickly.

D-Wave’s quantum annealer technology uses superconductors and requires precise and bulky refrigeration to keep the units at the optimum temperature of 15 millidegrees Kelvin. Another less powerful option are simulated annealers, which use software.

The U of T-Fujitsu Labs created digital annealer is a middle ground of sorts between these two approaches.

All three are “trying to search statistically or randomly through this huge space with some rules to find the minimum energy location and find the answer.”

“But the digital annealer we’ve designed is much faster than simulated annealing and it rivals quantum annealers at this point,” he said. “We also have the potential to go much bigger, much faster. For us [compared to D-Wave], the limitation [to scale up] is much less. The potential is quite high.”

The digital annealer can also slide into a regular PC — just like a graphics card — and supercharge its ability to crunch hugely complex optimization problems in a fraction of the usual time and for a much cheaper cost. And no refrigeration is required.

One of the first places he sees the digital annealer being used is in hospitals.

In the case of radiation therapy for cancer patients, the U of T-Fujitsu Labs created digital annealer will help health-care professionals more precisely calibrate the dosage and angle of beam radiation needed to “create maximum damage” to shrink tumours and kill cancer cells with little to no damage to surrounding healthy tissue, Sheikholeslami said.

But to arrive at the best treatment, which needs to be tailored to each individual patient, requires sorting through an estimated 100,000 bits of information to find the optimization point.

The number of possibilities you have with 1,000 bits of unknown information is 21000. That means the number of possible solutions is approximately a single digit with 300 zeroes in front of it — that’s how big it is, he explained.

“Today, a patient may need to wait an hour for this optimization to determine how the machine should direct its beams,” he said. “With this digital annealer, it could speed up the process from an hour to a few seconds. That’s the idea.”

It also has profound implications for banking by enabling financial experts the ability to quickly optimize their portfolios.

The ability to have a direct and positive impact on people’s lives is quite exciting for Sheikholeslami and his team of fellow researchers.

“Initially our work was quite hidden, deep inside your cellphones or your Presto card and you wouldn’t be able to see it. Now it’s coming to a point where it’s more visible — like something in a hospital” that can have a profound and positive impact on someone’s life, he said.

“Engineering is always about solving problems. We love problems and we love solving problems.”

— with files from Chris Sorensen

Engineering is a collaborative process, and effective teamwork is a key requirement for success. Professor Alison Olechowski (MIE) takes a scientific approach to understand how teams come together, and leverages that insight to give her students the tools and confidence they need to become enigneering leaders.

Olechowski recently joined MIE as an Assistant Professor, Teaching Stream, and is cross-appointed to the Institute for Leadership Education in Engineering (ILead). This fall, in addition to teaching an MEng course, she will be supervising a MIE491 Capstone team. Olechowski completed her PhD at the Massachusetts Institute of Technology (MIT) in Mechanical Engineering, where she studied the processes and tools that teams of engineers use in industry as they design innovative new products. Her research is wide-ranging, covering the automotive, electronics, aerospace, medical device and oil and gas industries.

Writer Liz Do sat down with Olechowski to learn more about what she hopes to accomplish at U of T Engineering:

What is your teaching focus?

This fall, I’m teaching a class for the ELITE Certificate for MEng students called “Leading Engineering Design Projects,” and I think that captures my teaching focus pretty well.

Being co-appointed at MIE and ILead means I get to focus on engineering design – which I really have a passion for teaching – and the ideas of project management. I think those topics lie at the intersection of mechanical and industrial engineering, and leadership.

Why is leadership so important to you and your teaching?

During my PhD, I studied teams of engineers in industry. I studied the ways teams come together to design complex new products with cutting-edge technology. I saw the technical design challenges that the teams were facing, but I also got to see how important leadership, teamwork and strategy were to the success of these projects.

It emphasized for me how important it is that we give engineering students the technical skills that they need, but also equip students the skills they need to work as a team and to flex their leadership skills, so they can have high impact and make change for the better.

What else are you focusing on?

I’m hoping to advise an MEng student at MIE. I’m interested in continuing studying what methods and tools engineers can use to be more effective designers. One of my big interests right now is collaborative computer-aided design (CAD) software.

Traditionally, CAD modelling was very solitary endeavor, with challenges such as version management and cumbersome installs. In recent years, CAD modeling software has finally caught up to the rest of the world and is starting to build cloud-based collaborative tools, and I think it’s really interesting to look at how you can go from something so solitary to having a team working on, let’s say, designing a 3D model.

We currently don’t understand how these teams should work together or communicate, or even what the composition of their team should be. We don’t even know if these new tools will lead to more innovative, higher quality, or less costly products. That’s something I hope to look at more closely with an MEng student.

Why did you choose U of T Engineering?

I looked for institutions with world-class students, research and teaching. U of T fit that bill for me, and I was excited to be in Toronto.

What do you hope to accomplish as an educator?

Part of my goal is to give students confidence. I want to empower them to tackle problems and remind them that a good engineer doesn’t just have a strong technical foundation. You also need to know how to lead, how to be creative and how to communicate. That’s what makes a solid engineer.

Professor Azadeh Kushki and her team have designed a prototype software application for the optical head-mounted display Google Glass as a social-skills coach to help children with autism spectrum disorder (ASD).

Their new study, published in the open-access journal Frontiers in Robotics and AI, finds that the wearable technology can recognize conversational prompts and provide the user with suitable responses in return. Moreover, children find it easy to operate and enjoy using it.

ASD is a life-long condition that affects one in 68 children. A defining feature of ASD is difficulties with social communication, which can include initiating and maintaining conversations with others.

“We developed software for a wearable system that helps coach children with autism spectrum disorder in everyday social interactions,” says Kushki, an assistant professor in the Institute of Biomaterials and Biomedical Engineering (IBBME) at the University of Toronto and the Mary & James W. Davie Scientist at Holland Bloorview Kids Rehabilitation Hospital. “In this study, we show that children are able to use this new technology and they enjoy interacting with it.”

Children with autism spectrum disorder are often drawn to technological devices and find them highly motivating tools for delivering interventions designed to help them. The problem with existing technology, however, is that using human-to-computer interaction to teach social skills can have the opposite effect to its goal, in that the user becomes socially isolated.

“The interesting thing about our new technology is that we are not trying to replace human-to-human interactions; instead, we use this app to coach children who are communicating with people in real-world situations,” explains Kushki. “Children can practice their skills outside of their normal therapy sessions and it can provide them with increased independence in everyday interactions.”

Kushki and her colleagues developed the app, named Holli, to be used with wearable technology such as Google Glass — a head-mounted display in the shape of eyeglasses. It listens to conversations and prompts the user with an appropriate reply.

For example, if the user is greeted by a person who says ‘Welcome’, Holli will provide various responses to choose from, such as ‘Hey’, ‘Hello’ or ‘Afternoon’. When Holli recognizes the user’s response, the prompts disappear and Holli waits for the next exchange in conversation.

To assess the usability of the prototype software, the researchers asked 15 children with ASD to be guided by Holli when interacting socially. They saw that Holli could complete most conversations without error, and that children could follow the prompts to carry on a social interaction. In fact, Holli was often able to understand what the user was saying before/he she finished saying it, which helped the conversation to flow naturally. As well as demonstrating its feasibility, the children also said how much they liked using it; they enjoyed the prompts and found it easy to use.

“This study shows the potential of technology-based intervention to help children with ASD,” says Kushki. “These systems can be used in everyday settings, such as home and school, to reinforce techniques learned in therapeutic settings.”

It is hoped that further developments will allow customization for individual users, such as changing prompt location, size and medium, to cater to each child’s unique preference and ability. In addition, more work is needed to improve Holli’s ability to deal with speech differences that can affect those with autism spectrum disorder.

“Technology has tremendous potential to change the way we think about delivering services to those with ASD. It can augment existing face-to-face interventions to make services accessible in a timely and cost-effective way and help increase treatment effectiveness,” concludes Kushki.

—This story was originally published by Frontiers and is reproduced with permission.

U of T Engineering’s Human-Powered Vehicle Design Team (HPVDT) has won the 2017 World Human Powered Speed Challenge. Their recumbent bicycle, named Eta Prime, was clocked at an impressive 127.6 kilometres per hour, the fastest in this year’s competition at Battle Mountain, NV.

“It is a great success for the team,” said Calvin Moes (MSE PhD candidate), Eta Prime’s pilot and captain of the Human Powered Vehicle Design Team. “We have never won this event before, and even though we did not a set a new world record, it is still an excellent accomplishment. I am excited to continue with the project and compete again next year.”

Eta Prime’s design is modelled on Eta, the vehicle that currently holds the record for the world’s fastest bicycle at 144.17 km/h. Eta was built by AeroVelo, a company founded by U of T Engineering alumni Todd Reichert (EngSci 0T5, UTIAS PhD 1T1) and Cameron Robertson (EngSci 0T8, UTIAS MASc 0T9).

Eta, which did not race at this year’s competition, was the result of a long-standing collaboration between AeroVelo and HPVDT, so was only natural that the team build on this expertise to create their next vehicle: they used Eta’s molds to cast Eta Prime’s carbon-fibre shell.

“Within a millimetre or two, it has exactly the same shape,” said Moes. “As far as we know, it is the best shape for a single-person speedbike in the world.”

Still, there were aspects of Eta that Moes and his teammates felt could be improved. They overhauled the carbon-fibre frame that holds up the vehicle and redesigned both the rear wheel and braking system. Through a combination of innovations, they were able to create a bike that was 20 per cent lighter than Eta, while maintaining its internal strength.

But as with any speedbike, much depends on the engine — that is, the rider. “You can build the best bike in the world, but if you can’t produce the energy to get it up to speed, you’re not going to get there,” said Moes.

To provide this power, many of the approximately one dozen teams in the World Human Powered Speed Challenge hire semi-professional cyclists. HPVDT does not, though Moes did undergo extensive training. Over the last eight months, he said he’s managed to reduce the gap in power output between himself and Reichert, Eta’s rider, by about half.

“The fact that we reach the same speeds as the other teams, and in some cases, even surpass them, on significantly less power than their riders can produce is remarkable,” said Moes. “It speaks to the amount of engineering that went into this design.”

Professor Jun Nogami (MSE) is the team’s faculty advisor, and travelled with them to Battle Mountain to act as a timekeeper.

“It is incredibly valuable for students to participate in design teams, and then to appear at international competitions,” said Nogami. “I’m proud of the way the team pushed through adversity to finish with the overall title. Congratulations to Calvin, who is the fastest person in the world for this year!”

Though the competition was intense, Moes said the atmosphere at Battle Mountain is friendly.

“That’s actually one of the best parts of the event,” he said. “We interface with the local community, and display our bikes to students in local schools. Teams will go and talk to each other, and inspect what new design features each bike has. It’s wonderful to be part of this elite group of racers, and learn from experiences that we wouldn’t get anywhere else.”

From pulp and paper to biofuels, many industries are based on turning renewable biomass — trees, plants, food waste — into energy and green materials.

But even though the primary feedstock of these industries is organic matter, inorganic contaminants such as salts and metals are commonly found in the fields and forests where these feedstocks grow. The presence of these contaminants in the process is not just a nuisance; they can damage process equipment, reduce overall efficiency and create environmental headaches for the surrounding community.

Professor Nikolai DeMartini deals with these problems, offering techniques and methods that industrial processors can use to safely remove these contaminants. Before joining U of T Engineering this year, DeMartini spent nine years at Åbo Akademi University in Finland. Writer Tyler Irving sat down with DeMartini to learn more.

Can you explain the focus of your research/teaching?

I work on the process chemistry of inorganics in the industrial processing of biomass and waste. This work is directly applicable to the pulp and paper industry as well as companies involved in converting biomass and waste into liquid fuels and electricity.

Inorganic chemicals — including salts and metals — are often mixed in with biological material. Their presence and behavior impacts energy efficiency, corrosion and emissions. A major goal of my research is to make changes to industrial processes that can effectively deal with these inorganic components and lead to improvements both for the companies and surrounding communities.

I am fortunate to have three new students working on topics related to the water chemistry of the chemical recovery cycle in pulp mills. Two are working on crystallization of salts and the resulting effects on heat transfer scaling within the plant. The third is studying the solubility of metals in pulp mill waters to better help industry in their removal strategies.

I plan to expand into some topics related to thermal conversion as I take on additional students next spring.

Why did you choose U of T Engineering?

The most significant draw for me is the quality of the people I have met in the Department of Chemical Engineering & Applied Chemistry, both faculty and students. Not only is the scientific level extremely high, but the collegiality is recognized as an important element in the department’s success.

The second factor was the close ties to industry as I enjoy working in the interface between companies and academia.

What do you hope to accomplish, and what are you most looking forward to in your new position?

Within the realm of student development, I hope to make the application of chemical engineering more tangible. I know that for myself, it wasn’t until my internships in industry that I started to see how the subjects I was working on in the classroom could be applied. Beyond that, I hope to have a positive influence industry and to see my students in leadership roles in the future.