As Torontonians get ready to head to the polls on October 27, issues that have been driving public debate and city politics over the past year are heating up.

Over the next four weeks, U of T News—reposted on Engineering News—will feature a mini-series of podcasts introducing experts from engineering, geography, architecture and more as they explain their boundary-breaking research with the aim of providing voters—and anyone interested in the future of cities—with a snapshot of what Toronto and other global cities could look like just a few years from now.

The first episode is all about traffic. You can download or stream the full episode here:

[soundcloud url=”https://api.soundcloud.com/tracks/170330981″ params=”color=00cc11&auto_play=false&hide_related=false&show_artwork=true” width=”100%” height=”166″ iframe=”true” /]

(Click the down-pointing arrow button in the player to download episode and transfer to your listening device)

Part One: Smarter traffic lights

In the first part of this episode, post-doctoral researcher Samah El-Tantawy (CivE) explains her work with Professor Baher Abdulhai (CivE) as they develop a system known as MARLIN-ATSC (Multi-Agent Reinforcement Learning for Integrated Network of Adaptive Traffic Signal Controllers).

The name sounds complicated but it’s really a simple idea: making traffic lights artifically intelligent.

She says traffic simulations have shown that MARLIN can reduce traffic wait times by 40 per cent—and it’s just about to be tested on the roads of Burlington.

Last year, El-Tantawy was featured in U of T News for winning an international award for her work on MARLIN.

Part Two: A new kind of ride on Toronto streets

Engineering alumnus Phil Lam (EngSci 0T9, MIE PhD 1T5) and his team at Wheelspan want to make travel on Toronto roads greener, safer and more efficient.

Their innovative human-electric hybrid vehicle and their company are both in development at the Impact Centre, one of U of T’s entrepreneurship hubs specifically designed for entrepreneurs focused on the physical sciences.

Lam explains the urban needs driving the mission of Wheelspan.

Part Three: Putting the politics of traffic into students’ hands

Professor Zack Taylor teaches urban issues and local government at University of Toronto’s Scarborough campus.

He’s interested in political questions and behaviour at a local scale –and he’s inviting his students to join him in his work.

This semester, Taylor is leading a fourth-year seminar course all about the Toronto election.

In this episode, he explains why he’s looking to students to help fill the gaps of scholarship on city elections and what it means for young researchers to dig in.

Read more about building successful cities at U of T.

This podcast features music made available on the Free Music Archive from artists Cheese N Pot-C, Tha Silent Partner and The Custodian of Records.

When you download photos from your digital camera, it may only seem like a click of a mouse. But to your computer, it’s an intricate process fraught with error. As millions of information bits travel between devices at lightning speed, tiny blips and blunders are common—and fixing those errors is more complex than you’d imagine.

ECE Professor Frank Kschischang is a pioneer in developing new coding systems that correct these errors—and his innovative work recently garnered him the role of University of Toronto Distinguished Professor in Digital Communication.

Granted by the office of the vice-president and provost for the University of Toronto, he will hold the position for a five-year term, effective January 1, 2015. The Distinguished Professor Awards are designed to advance and recognize individuals with highly distinguished accomplishments, who maintain an extraordinary level of activity in their research and scholarly work and have achieved pre-eminence in their fields.

Professor Kschischang has made seminal contributions in the area of error-correcting techniques, and his methods have been applied in wired and wireless systems, as well as optical networks. In the late 1990s, he co-invented the factor graph, a type of graphical model that implements an efficient probabilistic-inference algorithm for application in error-control coding, signal processing and DNA sequencing. Now a standard tool used throughout machine learning and digital communications, the factor graph has also been implemented in many industrial standards.

His award-winning work on subspace codes for network coding provided an elegant solution to the problem of error-control in communication systems. Using random linear network coding, it introduces a radically new approach to communications in networks like the internet. His research on optical communications has been equally groundbreaking, attracting attention from leading theoreticians and industrial practitioners. His published papers are influential and highly cited, and he has won several best paper awards.

Kschischang has received many awards and honours in recognition of his pioneering research contributions. He is a Fellow of the Institute of Electrical and Electronics Engineers (IEEE), the Engineering Institute of Canada and the Royal Society of Canada, and garnered a Killam Research Fellowship in 2010. He is a recipient of the Canadian Award in Telecommunications Research, given biennially to a top Canadian researcher in this area. A member of the first cohort of Canada Research Chairs at the University of Toronto, he was awarded the CRC in Communication Algorithms in 2001. Highly regarded by his peers, Kschischang was elected president of the IEEE Information Theory Society in 2010. He currently serves as editor-in-chief of IEEE Transactions on Information Theory, the most prestigious journal in his field.

In addition to his research accomplishments, Kschischang is one of the Faculty’s most accomplished and popular teachers. An excellent lecturer who receives outstanding teaching evaluations, he has also contributed to curriculum development. He was a key architect of the “flexible curriculum” and served for several years as chair of the Faculty of Applied Science & Engineering’s Curriculum Committee. He has received six departmental teaching awards over the years, as well as the Faculty Teaching Award. His remarkable record of teaching and research was recognized in 2010 with the University of Toronto Faculty Award.

With files from Carolyn Farrell and Marit Mitchell.

Often singled out for his academic leadership and research, U of T Professor Paul Santerre is being celebrated for a different reason this month. His leadership in moving his biomaterials discovery, Surface Modifying Macromolecules, to the marketplace has garnered him top prize from the 2014 Ernest C. Manning Innovation Awards.

The awards recognize Canadian innovators who have successfully created and marketed new concepts, processes or procedures. Santerre, from the Faculty of Dentistry and the Institute of Biomaterials & Biomedical Engineering (IBBME) (which spans the faculties of Applied Science & Engineering, Medicine and Dentistry), has been distinguished by this year’s $100K Principal Award.

Santerre’s discovery solves an important dilemma in medical care. When patients are fitted with tubing devices – used for everything from kidney dialysis to blood transfusions – the tubes can cause thrombosis (blood clots) to form. These clots can detach and lead to major complications or mortality. Current treatments involve coating devices with anti-coagulant drugs, such as heparin, that can strip away from the tubing and enter the body.

Rather than acting like a coating, Surface Modifying Macromolecules (referred by the trade name Endexo™) are added during manufacturing so that they are embedded throughout the device. The molecules don’t shed, and their success rate at preventing blood clots has been extremely high – reducing incidents of clots by as much as 87 per cent in blood loop tests, a lab test that simulates blood circulation in the body.

Santerre, who also won the NSERC Synergy Awards for Innovation for his research leadership in 2012, commercialized the intellectual property into a budding startup company, Interface Biologics, Inc., which then developed the molecular technology into several products. Garnering major investments, and then entering into licensing agreements with a leading U.S.-based biomedical device company, AngioDynamics, the company was able to develop the technology to a point that made it market-ready.

In the past two years the technology has jumped several major regulatory hurdles, including two approvals from the U.S. Food and Drug Administration (FDA), as well as similar approvals in Europe and Canada, and has quickly overtaken the market with strong interest. Within its first year of sales, Peripherially Inserted Central Catheters (PICC) containing Endexo landed 45 per cent in the Canadian market alone – and with new licensing partners, is set to steal a major piece of the dialysis market in the U.S., worth an estimated $2 billion.

Daniel Haas, Dean of the Faculty of Dentistry, dubbed Santerre’s latest tribute “fitting”: “Throughout his career here at the University of Toronto’s Faculty of Dentistry, as well as at IBBME, Paul has consistently demonstrated outstanding innovation in the field of biomaterials research that has brought him international recognition.”

The award recognizes Santerre as one of Canada’s leading inventors who has overcome the challenges associated with pushing his creation into the marketplace, and in turn, is helping to position Canada as a global leader in technology, business, engineering and social innovation.

It’s a job, Santerre admits, that’s not always easy.

“The Manning award is a recognition that the University of Toronto is driving and enabling the world class research of its academics to be translated into unique and transformative technologies for the health care field,” said Santerre, who urges decision-makers at all levels of government to “capitalize on the potential economic opportunities that exists in Canada,” especially those available through university research networks.

“Paul Santerre is a trailblazer in biomaterials and biomedical engineering,” said Cristina Amon, dean of the Faculty of Applied Science & Engineering. “Not only is he pioneering innovative research, but he is also transferring his findings directly to market so they can improve health care for people around the world. I extend my heartfelt congratulations on behalf of the Faculty for this richly-deserved award.”

“Paul Santerre is a talented and innovative research leader. The success of Interface Biologics is yet another example of how U of T-born research can lead to new clinical applications and economic success. I congratulate him on earning a Manning Award,” said Catharine Whiteside, Dean of the Faculty of Medicine and Vice Provost, Relations with Health Care Institutions.

Transforming intellectual property into booming businesses has become something of a trademark for the University of Toronto in recent years. The University consistently tops the rankings of North American schools for startup activity, according to research conducted by the Association of University Technology Managers (AUTM).

Read the full story on this year’s Manning Innovation Awards in Maclean’s magazine.

Most of us think of a classroom as rows of desks facing a podium or screen; students sit quietly, alternating between taking notes and listening to a professor lecture.

This is a model that all of us have experienced—but is it the best way to learn?

Eager to explore this question, U of T Engineering recently unveiled a pilot Technology Enhanced Active Learning (TEAL) classroom. TEAL rooms offer an innovative new educational method that facilitates collaboration and hands-on learning, assisted by technology and strategic design.

With several TEAL rooms expected in the forthcoming Centre for Engineering Innovation and Entrepreneurship (CEIE), the pilot project gives U of T engineering students and educators a taste of how the different format works

“The pilot room is a great chance for us to see the design in action,” said Steve Miszuk, director, facilities and infrastructure planning. “We can try out different layouts and technologies, get feedback and see what really works.”

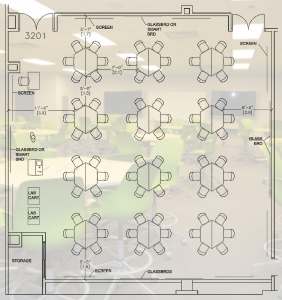

Located in the Sandford Fleming building, the TEAL room features bright green chairs clustered around 12 hexagonal tables that are spread throughout the room. This layout – an alternative to the traditional lecture-style of all tables and chairs facing one podium – encourages collaboration amongst students. And thanks to wheels on all chairs and tables, the room can be as flexible as needed, quickly adjusting for exam or tutorial formats.

“The new TEAL classrooms provide a great space for collaborative learning in tutorials or courses with small class sizes,” said Susan McCahan, vice dean, undergraduate. “There’s a lot of evidence to suggest that active, team-based learning is an effective model for students, and this is a great chance to implement those practices.”

In addition to changing the method of how students learn and retain information, TEAL rooms also invite instructors to rethink how they deliver material. Rather than remaining stationary near the front of the room, professors

are encouraged to move from table to table.

Eight 80-inch screens are spaced evenly around the room – two on each wall – to make material visually accessible to every student. And with tables set at bar-height, the instructor is able to engage students at eye-level rather

than leaning down or lecturing from above.

To further enhance the collaborative experience and enable peer-to-peer learning, every table is equipped with ports so that students can showcase their work easily on the digital displays.

U of T Engineering’s pilot TEAL classroom is already being heavily used, with over 35 hours booked per week across a number of departments and divisions.

“The TEAL rooms are one example of collaborative learning spaces we’re implementing around campus,” said Miszuk, who also mentioned new study areas in the Bahen Centre. “Keep an eye out for more projects in the future.”

The Engineering alumni behind a wearable device called the “Nymi” – a bracelet-style product that uses your unique heart rhythm as a password to unlock or active devices – secured $14 million in investment this week from key industry players including Ignition Partners, Relay Ventures and MasterCard.

Developers Foteini Agrafioti (ElecE MASc 0T9, PhD 1T1) and Karl Martin (ElecE 0T1, MASc 0T3, PhD 1T0) created the technology as a research project while studying at U of T Engineering; commercializing it through a startup they called Bionym.

The “Nymi” detects and distinguishes a person’s unique heartbeat (cardiac signal) through built-in sensors. It can be used to secure various devices with an accuracy greater than 99%, roughly the same as current fingerprint-enabled security systems.

“[Bionym’s] at the forefront of a revolution in identity-based interactions with devices and services and our momentum continues to grow,” said Martin, the startup’s CEO. “This round of financing is providing us with the resources needed to bring the platform to market.”

To understand how the “Nymi” went from idea to finished product, U of T News’ Brianna Goldberg spoke with Jesse Rodgers, director of the Creative Destruction Lab program at the Rotman School of Management, and Kurtis Scissons, entrepreneurship manager at U of T’s Innovations & Partnerships Office (IPO) and co-director of the UTEST accelerator for early-stage software companies. Through their roles on campus, both contributed to the startup’s significant success.

What qualities of promise did you see in Bionym in the early days when they worked with you?

Scissons: Obviously they have a very interesting technology but more so it was the great balance of technical skill with business drive within the founding team. Coachability was a key personality trait for Karl and his co-founder, who both listened, respected and appreciated when others took time to provide advisory support.

Rodgers: Bionym is founded on research. The determination and dedication it takes to do that research is a quality that has carried them to where they are today.

What’s been the key to their success, from your perspective?

Scissons: A few things. Their technology was both created and proven effective by world-class researchers at U of T, which gave it credibility. Their timing was also impeccable. Wearable computing is a burgeoning industry and there is a growing interest in it in light of prevalent security issues and data breaches with current state of the art authentication protocols. Their ECG model is a novel approach.

Finally, they had a great team. The founders had the right mix of talent and passion for entrepreneurship. Today the team has continued to grow “organically,” meaning that the roughly 40-person Bionym team continues to find talent primarily from the University of Toronto. They are a great example of entrepreneurs that fully took advantage of the entrepreneurship eco-system here at U of T by engaging with the Innovations & Partnerships Office, the Creative Destruction Lab, Next36 founders and MaRS.

Rodgers: They have been successful at raising capital from great investors and building interest in their product. Those are great first steps towards long-term success. They got there with a positive attitude, a desire to learn and be coached, and a vision on how their research can used by everyone.

What does the Bionym example say to the young companies you’re working with at UTEST and Creative Destruction Lab?

Scissons: This is not an overnight success. The technology was developed for years within the U of T Biometrics Security Laboratory. The team came up against challenges in the early commercialization days but overcame them. Their successful pivot is a strong example for current UTEST companies that may struggle. Karl Martin also continues to give back to the U of T entrepreneurship community, lending his time to speak with and advise current UTEST companies.

Rodgers: At the Lab we use their personal growth in understanding research alone isn’t enough to build a company with; a product mindset is essential. That change in thinking towards product has helped the company grow to where it is now.

Learn more about entrepreneurship at U of T Engineering.

In Canada, we often take safe drinking water and a stable food supply for granted. But in many parts of the world, people are much less fortunate.

Two recently announced Grand Challenges Canada (GCC) grants will allow U of T Engineering researchers to bring their expertise to bear on some of the most urgent global health issues using scientific, technical, social and business innovation.

The grants were included in the latest round of GCC grants, with two previous grants this year given to U of T engineers for new methods that detect defective drugs and a 3D printer that makes skin grafts.

The latest two project teams will receive $112,000 in seed funding to implement their innovative products in the developing world.

Fighting childhood malnutrition one bottle at a time

Breast milk is a complete meal that gives infants all they need to thrive. But millions of women in the developing world must return to work quickly – which means the end of breastfeeding and the start of malnutrition that can have life-long effects for the child.

A new project in Dhaka, Bangladesh, called Mother’s Milk will install hospital-grade breast pumps in factories where women work, along with a simple heating system so that breast milk can be pasteurized on site in as little as 30 seconds. Mothers will be able to safely store the milk to help feed their babies when they are away from home.

“Our goal is to lower the rate of infant malnutrition,” said PhD student Scott Genin (ChemE PhD 1T5), a member of the project team. “As a side benefit, we anticipate that factories with this system will also have lower worker turnover, as this will be an attractive benefit for their workers.”

The design was created through the ‘Interdisciplinary Approach to Global Challenges’ course offered through the Centre for Global Engineering – where the Mother’s Milk project team of Scott Genin, MBA student Puja Madhok (Rotman School of Management), and Master’s students Micaela Collins (Dalla Lana School of Public Health) and Marta Blackwell (Munk School of Global Affairs) first met. The group is led by Professor Joseph Wong (Munk School of Global Affairs) and Dr. Sabrina Rashid (International Centre for Diarrhoeal Disease Research, Bangladesh).

https://www.youtube.com/watch?v=0LM1uBnvRok

Trying to clean up drinking water? Turn to the sun

Yu-Ling Cheng (ChemE), director of U of T’s Centre for Global Engineering, is working with collaborators in Bangladesh to address one of the most serious health issues in the developing world: access to clean drinking water.

In areas like coastal Bangladesh, large parts of the population depend on rainwater that is collected from roofs during the rainy season and stored in cisterns for use during the months-long dry season. Often this rainwater is not very clean to begin with, and nasty pathogens can multiply in the water during the long months of storage, creating an even greater health hazard for millions of people.

Professor Cheng’s team is harnessing the sun’s UV light to improve the quality of the water as it is collected, treat it during storage and then further decontaminate it just before it’s consumed. Called Enhanced Solar Disinfection (eSODIS), the method will use ingenious cistern design and a small “just-in-time” solar-activated disinfection/dispensing module to increase the effectiveness of UV disinfection.

“I am proud of all of the projects that have come out of the Centre for Global Engineering, including the two being funded here by Grand Challenges Canada,” said Cheng. “They are examples of really important problems in the developing world where the skills and expertise of our faculty members and students can be applied to great effect.”

https://www.youtube.com/watch?v=J7p1YJB5LQY