When engineering science student Kimberley Cota (EngSci 1T7) decided to travel halfway across the globe for a summer research exchange in Singapore, she never imagined what would be waiting on the other side – a vibrant alumni community eager to engage with their alma mater.

Earlier this month – and two days after Cota’s arrival – the Singapore alumni group announced their donation of a ‘Singapore Malaysia Alumni Room’ in the forthcoming Centre for Engineering Innovation & Entrepreneurship (CEIE). The group has already exceeded their fundraising goal of $250,000 by close to $85,000.

Local alumni held a celebratory event, attended by U of T Engineering Dean Cristina Amon; the Honourable Heather Grant, Canadian High Commissioner to Singapore; as well as alumni and students, like Cota, on exchange at the National University of Singapore (NUS).

“The best part of the event was talking to U of T alumni who are now based in Singapore,” said Cota. “Their perspectives on the value of an engineering education at U of T were inspiring. Talking to them also gave me a deeper insight into some of the career paths that EngSci graduates take.”

Jianwei Sun (EngSci 1T6), a second-year student also on exchange at NUS, said the event demonstrated how greatly U of T values its students.

“The personal meeting with the dean and high commissioner shows how strongly U of T cares about its relationships. Not only to other countries and universities, but also to its own students.”

The summer research exchange program at NUS, which was established in 2008 and strongly supported by U of T’s Centre for International Experience, gives EngSci students the opportunity to conduct research at one of the world’s top universities, while providing incomparable cultural experiences and networking opportunities. More than 42 students have embarked on the exchange since its inception.

The reception in Singapore was just one of many for Dean Amon. Following a successful trip last November, she returned to Asia-Pacific to reconnect with alumni in Hong Kong and Taiwan and to recognize their support of the CEIE. In addition to Singapore’s achievement, Hong Kong alumni have raised just over $4 million of their $5 million goal, while Taiwan grads have raised $125,000 of their $300,000 goal to date.

“The Centre for Engineering Innovation & Entrepreneurship will take engineering education and research to a new level, providing the physical space to strengthen collaborative learning, stimulate innovation and foster entrepreneurial endeavours,” said Dean Cristina Amon. “We are tremendously grateful to have received such strong support from our Asia-Pacific alumni.”

Make a donation to the CEIE.

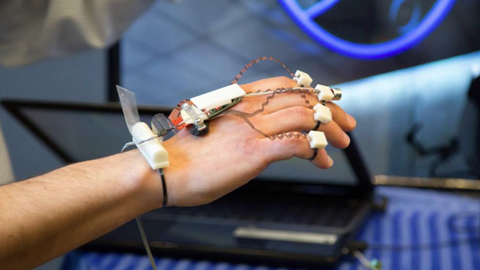

demonstrates ExoGlove at Rotman’s Creative Destruction Lab (Photo:

Graham Huber).

As he rotates his palm upwards and wiggles his fingers slowly, Martin Labrecque’s hands take him down the dark alley of a video game. One finger flicks two zombies into oblivion, another heals a teammate – all without cumbersome controllers.

Welcome to the ExoGlove, an early-stage invention from U of T Engineering alumnus Martin Labrecque (CompE MASc 0T5, PhD 1T1). The prototype uses a “glove” of sensors that could soon help surgeons, video editors, gamers and those with diminished motor skills interact more intuitively with technology.

The ExoGlove is one of five projects that recently received Heffernan Commercialization Fellowships, a program that awards promising inventors with $32,000 to develop their products into viable businesses.

The fellowships are part of a $5 million gift to the Faculty from U of T Engineering alumnus Gerald Heffernan (MMS 4T3), and they continue to enable graduate students to transfer their research into new Canadian technology companies.

Past recipients have included James Dou (ECE MASc 1T6), whose disease-detecting biomedical devices led to founding the company ChipCare; and Carlos de Oliveira (CivE MASc 0T6), who worked alongside Professor Constantin Christopoulos (CivE) to develop earthquake-resistant structural casting, founding Cast ConneX.

Take a closer look at this year’s five projects receiving Heffernan Commercialization Fellowships:

ExoGlove

Martin Labrecque (CompE MASc 0T5, PhD 1T1)

A promotional video from Breq Labs Inc. highlights the many uses of ExoGlove.

With ExoGlove, a doctor can interact with a computer screen in the middle of surgery or an elderly person could answer a call by holding her hand in the phone symbol. The device allows users to control a computer simply by moving their hand.

Despite its name, Labrecque’s invention is not an actual glove. It’s a clip-on wireless attachment consisting of five rings – one for each finger – connected by wires that fasten around the wrist. It does not interfere with the palm of the hand, so it can be used easily in combination with other tools.

Because it does not use cameras to track movement, the ExoGlove has no line-of-sight issues like other motion-tracking tools currently in development. It can be used with any level of light, and with any USB-compatible device.

“Working on other people’s start-ups taught me a lot about what works and what doesn’t,” said Labrecque. “I think business knowledge is very important. Equally valuable, though, is being able to connect with people who are good in the areas where you lack.”

Labrecque hopes to have ExoGlove in mass production and on the market within the year. Gamers are his initial target, but secondary markets include those with accessibility issues, rehabilitation, 3D rendering, video editing artists and much more.

A new catalyst for carbon-carbon bonds

Adam McKinty (Chemistry PhD 2013)

Forming carbon-carbon bonds – best understood as chemical reactions that join carbon atoms together – is important to the manufacturing process in many industries, including pharmaceuticals, cosmetics, plastics and more. Forming these bonds can make bulletproof plastics, and even turn canola oil into diesel fuel.

Despite their wide application, there are few technologies available capable of catalyzing – or creating – these valuable bonds, with one of the major methods controlled through a single company’s monopoly.

Adam McKinty (Chemistry PhD 2013) has developed a new method to perform virtually the same bonding reactions as this monopoly company, and at a low cost – called olefin metathesis – in partnership with his advisor Professor Douglas Stephan (Chemistry).

Their technology has already demonstrated success in a number of uses, and the next step is using the powerful method across a wide variety of applications in order to showcase its impact to potential buyers.

Commercializing a new organic electronic material

Andrew Paton (ChemE PhD 1T3)

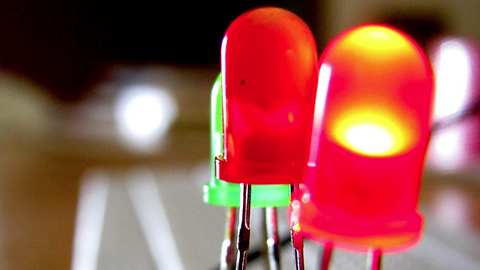

Many of our modern solar cells and LEDs – which use non-organic semi-conductors made from silicon – are becoming less desirable for use in the next generation of technology. They require high processing temperatures and return on investment can take up to 30 years.

In Professor Tim Bender’s (ChemE) lab, Andrew Paton (ChemE Phd 1T3) and colleagues are developing organic semi-conductors with fewer materials, making them smaller and more cost effective for tomorrow’s electronics. Made out of organic components, they also have high conductivity and light absorption, properties which allow for thinner and more flexible television screens and monitors.

Paton is exploring several commercialization streams for his product, including organic light-emitting diode (OLED) and organic solar cell (OSC) manufacturers.

Novel ways to communicate with patients in an MRI

Garry Liu (MedBio PhD 1T3)

Being inside a magnetic resonance (MR) imaging suite can be an intimidating experience for many. The small space is uncomfortable, and the noisy operation of the scanner makes intercoms ineffective. To allow for audio communication, wireless headsets initially appear appropriate, especially due to the clinician’s limited mobility within the suite. However, an electromagnetic shield around the scanner room, called the “Faraday Box,” makes this particularly difficult.

Thinking outside that box, Garry Liu (MedBio PhD 1T3) proposed a wireless communication headset that is magnetic-resonance safe and does not interfere with the MRI’s functionality. This reduces stress for the patient, while increasing efficiency for the technician.

Interventional procedures inside a MR imaging suite are becoming more common. Many therapies turn to MR imaging to provide soft-tissue visualization without the damaging effects of radiation. In such a rapidly growing field, Liu’s mentor, Graham Wright (IBBME) sees a great deal of potential in the product.

Liu seeks to incorporate his technology in all local interventional-MRI sites, such as Sunnybrook Health Sciences Centre and the Princess Margaret Hospital. He will approach them with demonstrations of early-adopter material and, through the niche research network, continue to market the technology at tradeshows and events.

Improving drug screening using microfluidics

Oleg Chebotarev (MechE MASc 1T2)

Testing and releasing a new drug can cost the pharmaceutical industry up to $1 billion – with only one in approximately 10,000 drugs ever reaching market. Often, this time and money is wasted due to poor drug testing platforms that don’t reflect the environment in which the drug will be administered: the human body.

That’s why Oleg Chebotarev (MechE MASc 1T2) developed a new platform for drug screening – one that closely resembles the conditions of common drug target organ tissues (brain, liver, vasculature, etc.). This commercially viable system has seen remarkable results, and enables early stage drug discovery because of its similarity to human physiology.

Chebotarev plans on marketing his technology to pharmaceutical and therapeutic biotechnology industries. He’s already piqued the interest of several companies, and continues to develop both the technical and business sides of his enterprise.

The Heffernan Commercialization Fellowships encourage development of Canadian technology-based start-ups by asking professors to nominate students and their promising ideas. The professors then mentor the students through the process of development, availing them of expertise, resources and feedback.

Read more about this year’s fellowship opportunities, as well as on Gerald Heffernan and his significant contribution to the forthcoming Centre for Engineering Innovation & Entrepreneurship.

Ten.

That’s how many iterations 15-year-old Maya Burhanpurkar went through to design an experimental apparatus that demonstrates a previously elusive physics concept – winning the Platinum Award at last week’s Canada-Wide Science Fair.

Burhanpurkar’s project, titled “Time-Integral of Distance: Uncovering A New Property of Fundamental Physics”, was guided by professor Steve Mann and PhD student Ryan Janzen (both ECE), in collaboration with Brad Bass of Environment Canada and the International Panel on Climate Change.

The award-winning project validated the concept “absement”, a term originally coined by Professor Mann to describe the time-integral of distance, which was historically a mysterious phenomenon.

“Professor Mann had been thinking about the possible influence of the time integral of displacement in nature, mostly music, for a few years already,” said Burhanpurkar. “I came up with the design of a novel experimental apparatus consisting of a fluid reservoir with a microprocessor-controlled, linear valve whose motion resulted in the precisely controlled release of fluid at continuously varying, pre-programmed rates.

“I built about ten iterations of the device before finally getting it right.”

Since the days of Sir Issac Newton, we have known that the time-integral of acceleration is velocity (shown by the formula a=Δv/Δt), and the time-integral of velocity is distance (v=Δd/Δt), yet the time-integral of distance has remained an elusive concept. This is the first time the change in distance over time had been demonstrated in physical space.

Burhanpurkar took top honours at last year’s Google International Science Fair with the same project, but winning at this event was still a thrill. “I was beyond excited!” she said. “I had won the Grand Platinum award a couple of years ago at the national science fair, so I was really surprised to be given it again.” She also brought home several category awards, including the Discovery Challenge Award, the Actuarial Foundation of Canada Award, a Gold Medal and university scholarships.

The mentor group met with Burhanpurkar several times to discuss the project design in advance of the fair. She and Janzen spoke frequently, especially as she picked up the calculus necessary for the work. Their next goal is to get the work published.

“We’re happily continuing to work with Maya as well as some new students, and would welcome any additional highly-gifted students to apply absement to other areas of biology, physics, ecology and medicine,” said Janzen.

Watch Burhanpurkar’s recent invited talk at TEDxYouth@Brampton.

It may have hydrogen fuel cells, a solar panel and three lithium-ion batteries, but a new electric vehicle from students at U of T won’t be found on the highway – it’ll be working on the farm.

A group of engineering students has proposed a new type of sustainable soybean harvester, recently winning first place in a unique graduate design course on campus. The machine produces zero emissions while powering its driving, threshing, storage and cleaning phases.

The idea was born in MSE558: Nanomaterials in Alternate Energy Systems, a course that brought together students from various engineering disciplines, including exchange students from Brazil’s Science without Borders program. It took participants outside their comfort zones of engineering problem-solving, and added business skills development such as market analysis, branding and education.

Now in its tenth year, the course taught by MSE professor Steve Thorpe is modeled after the National Hydrogen Association Design Contest and puts students through the whirlwind experience of launching a start-up.

It was the “Dragon’s Den” of engineering – not only did Engineering students Shahed Mirmohammadi (ECE 1T4+PEY), Jonathan Hoo (MSE 1T0, MEng 1T6), Renan Gomes (Science Without Borders – Brazil) and Ricardo Barnasky (SwB – Brazil) have to invent the potentially world-changing combine, but they had to sell a team of judges on its business viability, safety and practicality.

The sheer scope of the challenge and the chance to apply new nanomaterials to a real product appealed to Gomes. Like Barnasky, he is a Brazilian exchange student studying at U of T through the Science Without Borders program.

“Nano is never easy – it’s always complicated, but that’s the future,” said Gomes. “Our job as engineers is to learn how to solve problems using these new technologies.”

PURE – Powerful, Unique, Reliable and Efficient

All four team members shared excitement about the vision of greener farming with international impact, and their first task was to define their corporate identity. They dubbed their new company PURE, for Powerful, Unique, Reliable and Efficient.

Hoo, the team’s technical lead, conducted extensive research into load profiles of the current state-of-the-art machines, including phoning competitors, who wanted to sell him a combine, and Ontario’s Ministry of Agriculture & Food. The team even phoned the Brazilian government to inquire about a similar project there.

“Was it like detective work? No, it was like espionage,” said Hoo. “The harvester, you don’t just drive it – you have to cut the crops and process them and store them in a tank and empty them. Our load profile was pretty complex.”

Mirmohammadi said: “I learned so much about hydrogen fuelling, fuel cells, hydrogen storage and the issues with it, the cost of actually doing something like this. It’s doable, but it’s very expensive at this time.”

Pitching time

Similar to the television show Dragon’s Den, Team PURE presented their ideas to a panel of judges – including Professor Thorpe, Amy Jiang of BP and Alex Ayers of Pratt & Whitney. For Barnasky and Gomes, it was the first professional presentation they had ever delivered in English.

“These people are sharp, they know their stuff — if you screw up, they’re going to pick up on it,” said Hoo.

After handling a 20-minute question period with the judges, the team emerged victorious, winning an engraved plaque and $180 in prize money.

The second-place team designed a food truck serving First Nations cuisine to Bay Street bankers without using an atom of fossil fuels. The third-place team invented a zero-emissions personal-delivery drone.

Holistic solutions

“The whole point of this is to come up with a holistic solution,” said Thorpe. “We teach tools for screening new ideas quickly and performing failure analysis… keeping them in the box is challenging!”

Mirmohammadi said the course opened the team’s eyes to the incredible complexity of creating a product like this.

“If you were in a firm and you had all these different departments you work with, you can’t ever come up with one option thinking, ‘It’s technically feasible, let’s do it!’ Well, did you take into consideration that this is going to kill 100,000 fish? Or you’re going to have to spend billions of dollars trying to get the infrastructure to even build this thing. That’s definitely something that we’ve never done before.”

Despite the trial, would they enter this Dragon’s Den again?

Absolutely.

A U.S. entrepreneur has been garnering headlines around the world for a product called “palcohol”, a powdered alcohol that can be turned into a cocktail by adding water.

The University of Toronto’s Dominic Ali sat down with food engineer and Professor Emeritus Levente Diosady (ChemE), to learn the basics of how alcohol and other beverages might be produced and sold in the future.

For the past three months, Diosady has been developing iron-fortified tea to prevent iron deficiencies around the world – an idea that could be as important to public health as adding iodine to table salt to prevent thyroid problems.

Is powdered alcohol really possible?

Yes. Alcohol can be encapsulated – as in brandy-filled chocolates – or in miniature, as in the flavour buds in instant puddings.

As the details of the technology for powdered alcohol is not revealed in the [inventor’s] video, I have to rely on my basic knowledge of similar products. In any case, it is clear that alcohol – which is a liquid at normal temperatures – has to be “contained” in either microcapsules or inside an absorbent, both of which add to the volume of the product. Also, it must be edible and not add to the flavour or colour of the product.

How could it be created?

One of two approaches is possible: the alcohol is absorbed in a solid or, more likely, it is microencapsulated. In both cases, you need to contain it in a material that dissolves in water.

Considering “instant” refreshments such as Kool-Aid drink crystals have been around for decades, why hasn’t this been attempted before?

The trick is to find an encapsulant that dissolves in water, but is not dissolved by alcohol. It also needs to be neutral in taste and, of course, safe for human consumption.

What are some of products that you’ve found to be revolutionary from a food engineering perspective?

The most pervasive over the past 25 years has been aseptic packaging – this is the technology for the small juice boxes, soups and milk that do not need refrigeration. Microencapsulation for flavours and bioactive ingredients is another broadly-used technology. For example, live cells are encapsulated and added to yogurt to promote digestive health. Many ready-to-eat products rely on novel packaging and preservation technologies – think of microwaveable frozen entrees, such as Lean Cuisine or Café Steamers, which can be taken from the freezer and zapped to provide a complete meal.

Alcohol is used in different industries apart from drinking, such as a fuel, for example. What are some potential ways powdered alcohol could revolutionize different industries?

In most industrial situations, shipping large quantities of liquid is actually simpler and cheaper than shipping a powder. There may be an advantage in reduced flammability, but this depends on what the alcohol is coated/absorbed with. And reconstituted “palcohol” is too dilute to be used as fuel.

I can see powdered alcohols in windshield washer fluids, but that is a very low-value product, and I don’t see a huge saving in shipping the concentrate, rather than the finished product.

The idea of using powdered alcohol in an emergency medical situation faces the difficulty of finding safe water to reconstitute the alcohol. In most disasters, clean water is harder to find than medical alcohol.

I am sure there will be clever entrepreneurs who will find niche markets for products made with powdered alcohol. I expect that these will come in the food and beverage sectors. Clearly, powdered alcohol is a clever product, and should get a lot of sales from its novelty, much more than from its practicality.

So would you try “palcohol”?

I would try it, for fun. My poison is wine or cognac, neither of which is likely to be powdered.

Read more about Diosady’s recent food engineering research on iron-fortified tea.

A Canadian pioneer in nuclear chemistry with an inspiring love for science and engineering, Professor Emeritus Robert E. Jervis (ChemE) passed away May 21 on his 87th birthday.

Professor Jervis was born in Toronto and raised during the depression years. He obtained an undergraduate degree in math, physics and chemistry in 1949, an M.A. in 1950 and a PhD in physical chemistry in 1952, all from the University of Toronto. He subsequently worked at the Chalk River nuclear research facility, where he used applied nuclear chemistry to develop novel methods of trace element analysis in the environment.

Jervis joined U of T’s Department of Chemical Engineering and Applied Chemistry in 1958, where he continued his research in applied analytical and environmental chemistry for the next five decades. His research focused on the peaceful use of nuclear energy in industry, life sciences and forensic sciences. His work on human exposure to heavy metals garnered him significant national and international recognition.

Jervis also pioneered the use of trace elements to identify sources of pollution, and to assess the environmental impact of fossil fuel combustion. He similarly developed this technique in forensics, where he used trace elements in hair as bioindicators of exposure to environmental pollutants. This method was used to study arsenic levels in gold miners, mercury in aboriginal people and lead in urban children.

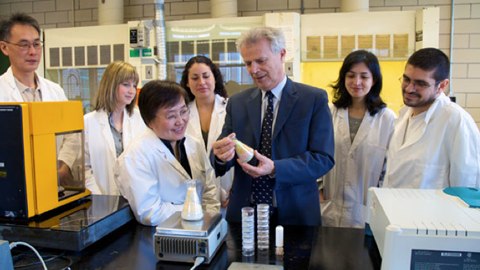

Professor Robert Jervis (left) with students at Chemical Engineering Open

House, 1964 (Photo: Heritage University of Toronto).

Jervis’ work took him around the world lecturing and consulting with scientists and scientific bodies, and as a visiting professor at the University of Tokyo, University of Cambridge and University of Kuala Lumpur. He published over 250 scientific papers.

He also received numerous awards and honours throughout his career, including: the Lewis Medal, Canada’s highest nuclear scientific award; the international Hevesy Medal, for radioanalytical chemistry; the American Nuclear Society’s Emmon Medal; and, the inaugural Russian Academy of Science’s Ressovsky Medal. He was a fellow of the Royal Society of Canada, the Canadian Nuclear Society, the Canadian Society for Chemistry and an honorary fellow of the Atomic Energy Society of Japan and the Indian Academy of Sciences.

Jervis’ deepest professional satisfaction came from inspiring first-year students to love the field of science. As a testament to the impact he had in the classroom, in 1992 a group of his former students established the R.E. Jervis Award, which recognizes a graduate student each year for outstanding work in nuclear engineering, with support from the Canadian Nuclear Society.