Former U of T Engineering dean, renowned expert in aerodynamics and beloved mentor, University Professor Emeritus Bernard Etkin (UTIAS) passed away on June 26, 2014.

Etkin led an accomplished career that spanned 50+ years of aeronautical research, consulting, teaching, and academic leadership. A graduate of the Faculty’s engineering physics program, Etkin joined the University of Toronto Department of Aeronautical Engineering in 1942, and helped Professor Gordon Patterson found the Institute for Aerospace Studies (UTIAS) in 1950. He served as dean of the Faculty from 1973-1979.

Professor Etkin’s pioneering research on aerodynamic theory led to 11 patents and three widely used books on flight dynamics, one of which – Dynamics of Flight: Stability and Control – has been translated into many languages and, now in its third edition, is still cited around the world as one of the seminal texts in the industry.

One way that Etkin applied his groundbreaking research is through the invention of the “infrasizer.” Resembling a wind tunnel, it allows users to sort particles based on weight and resistance to airflow, as heavier particles fall before lighter ones. With this technology, Etkin founded a company called Infrasizer Ltd. that has aided in manufacturing across a variety of industries.

As an expert in aeronautics and astronautics, he contributed to the design and production of two glider aircraft, including the deHavilland Sparrow, and a number of Avro aircrafts, including the AVRO Arrow.

Etkin was also part of the UTIAS team that helped to rescue Apollo-13 when an in-flight explosion damaged the craft and the service module became crippled. Etkin and the UTIAS team of professors performed crucial calculations on the correct pressure needed to separate the entry module from the damaged spacecraft which, ultimately, allowed the astronauts’ safe return.

Etkin’s contributions to his field have been recognized across Canada and around the world. He was a Founding Fellow of the Canadian Academy of Engineering and a Fellow of the Royal Society of Canada, the American Institute of Aeronautics and Astronautics and the Canadian Aeronautics and Space Institute. He was inducted into the Order of Canada in 2003.

In addition to research, Etkin was also a renowned educator and valued mentor. Even during his time as dean of engineering, he continued to teach a first year mechanics course, and his impact on the lives and careers of aspiring engineers is immeasurable.

“One of the greatest things about Ben [Etkin],” said Professor Gabriele D’Eleuterio (UTIAS), “was his skill as a teacher and mentor. He had an incredible ability to crystallize a thought and communicate it. He was a cherished mentor to many and he delighted in teaching and exploring science and engineering.”

Etkin’s passion for education also translated into many administrative changes in the Faculty. During his time as dean, he played integral roles both in changing the engineering curriculum from the “year system” to the “semester system,” and in introducing the M.Eng. degree. He also developed several laboratory and lecture courses, designed and managed the installation of the U of T subsonic wind tunnel, and made a strong effort to attract more female students into the profession.

In addition, he was an advocate of professional experience for engineering students and was pivotal in organizing a successful pilot program, which later became the Professional Experience Year (PEY), a program undertaken by nearly two thirds of undergraduate students today.

Even well into retirement, Etkin continued to inspire his colleagues and pursue research in areas both within his field and beyond, including global warming and climate change.

“Bernard Etkin will be remembered for his extraordinary contributions to the U of T community, the engineering profession and the world,” said Dean Cristina Amon. “On behalf of the Faculty, I send my deepest condolences to his family.”

Flags at the University of Toronto will be flown at half-mast on July 10 in honour of Professor Etkin.

From aerospace and biomedical engineering, to robotics and vehicle dynamics, mechanical engineers contribute to many industries that touch our lives everyday.

From June 1 – 4, U of T Engineering welcomed over 400 mechanical engineering students and academics for the biennial . With delegates joining from 14 different countries – including as far as China, Nigeria, the Netherlands and Iran – the four-day conference saw presentations of more than 350 research papers from across the field.

The CSME International Congress facilitates networking and the dissemination of research and new technologies amongst universities, industries, government agencies and R&D laboratories.

This year, the CFD Society of Canada – a forum for researchers in the area of computational fluid dynamics – also held their 22nd annual conference in conjunction with CSME.

“It was a unique opportunity to bring together CFDSC and CSME,” said Markus Bussmann, vice dean, graduate studies, and chair of this year’s CFDSC conference. “CFD encompasses a broad spectrum of application areas, and many of the papers presented as part of CSME, are of equal interest to CFDSC members. It was a successful experiment, bringing the two societies together for one joint conference.”

U of T Engineering Dean Cristina Amon was one of six keynote speakers at the event. She addressed attendees on the topic of engineering education, sharing the importance of diversity and system-thinking, as well as instilling professional transferable skills including global outlook, leadership and entrepreneurship. Other keynote speakers included Elliot L. Chaikof, Harvard University, and Grétar Tryggvason, University of Notre Dame.

Dean Amon and Professor Jean Zu, chair of mechanical engineering at U of T, also took part in a special panel discussion during symposium session on women in engineering. Organized by Christine Wu, University of Manitoba professor and president of CSME, the special session included a keynote address by Catherine Mavriplis, a University of Ottawa professor and NSERC/ Pratt & Whitney Canada Chair for Women in Science and Engineering. Professor Mavriplis shared new initiatives that are underway in both academia and industry that demonstrate positive approaches to promoting women’s advancement to leadership in engineering.

During the conference banquet, which recognized recently named CSME fellows and award winners, the CFD Society of Canada honoured Professor Dominique Pelletier, École Polytechnique de Montréal, with a Lifetime Achievement Award. He was recognized as an individual who has made outstanding time-enduring contributions to computational fluid dynamics in Canada, and he is only the third recipient of honour in the 22-year history of the society.

Additional events included a reception at Hart House, a research poster showcase by MIE graduate students, mechanical engineering lab tours, an NSERC information session and special musical performances by the U of T Engineering Iron Strings quartet and Skule Jazz combo.

“We are very proud to have hosted a productive and successful CSME and CFDSC,” said Professor Jean Zu, chair of the this year’s Congress. “By bringing both national and international researchers together, we understand more deeply the importance of learning from the expertise of our engineering colleagues.”

The next CSME International Congress will be hosted by the School of Engineering at the University of British Columbia, Okanagan in 2016.

From former industrial sites to rail yards and abandoned gas stations, there are an estimated 22,000 environmentally contaminated sites across the country. These areas are polluted with hazardous chemicals that could impact human health, ecosystems and the drinking water supply.

To help remediate these sites, the University of Toronto has been awarded $1.65 million from the Natural Sciences and Engineering Council (NSERC) to support student training and research in environmental clean-up.

Civil engineering Professor Brent Sleep will oversee the establishment of the Remediation Education Network (RENEW) with the funds, which come from NSERC’s Collaborative Research and Training Experience (CREATE) program.

“At the really old contaminated sites,” said Sleep, “hazardous wastes were not properly managed, often being disposed of in unlined pits or buried in drums that eventually rusted, leaking contaminants into the environment. More recent spills have been caused by accidents like pipeline leaks and train derailments.

“The problem with many groundwater contaminants such as chlorinated solvents is that once they’re in the ground, they stay there for a long time, because they’re fairly recalcitrant,” he said. “They’re trapped in the subsurface as pools of liquid that are slowly dissolving into the groundwater. They may also produce vapours that may be hazardous.”

The NSERC funding will support 42 master’s students, PhD students and postdoctoral fellows over six years. Many of them will attend U of T — the first cohort will be admitted for the

2014-15 school year — and will study with Sleep or with co-investigators Professors Elizabeth Edwards and Edgar Acosta (both ChemE) and Professor Barbara Sherwood Lollar of Earth Sciences. Some will attend Queen’s, Western and Waterloo and study with project partners there.

At U of T and their home universities, students will conduct research into the hydrogeology, chemistry and microbiology of contaminated sites and into processes that might be used to remove the contaminants or transform them to harmless compounds.

Students will also spend 20 per cent of their time working with partner companies. RENEW has established partnerships with seven environmental remediation companies to provide internships for the students, giving them practical experience in site assessment and clean-up.

“The companies are interested in the research,” said Sleep, “but they are also interested in attracting qualified students who may someday work in the industry.” Currently generating $1.7 billion in revenue per year, environmental remediation is a growing sector.

Students will also be trained in skills like project management, communication and leadership, preparing them for both academic and non-academic careers.

“The CREATE program not only brings benefit to U of T in the form of student support and training,” says Professor Peter Lewis, the university’s interim vice-president, research and innovation, “it tackles some of society’s most pressing problems. In this case, we will be training students to better understand and address a critical environmental challenge from within universities and from within industry. Congratulations to Professor Sleep and his colleagues and thank you to NSERC for this investment.”

Some of the RENEW students will continue work begun by Sleep at a former petrochemical plant contaminated with a variety of chlorinated solvents, many of which are carcinogenic. At the site, a reactive form of iron was injected into the soil, where it reacted with the chlorinated solvents and transformed them into harmless components. Sleep believes this also created conditions that stimulated naturally-occurring bacteria to provide additional remediation of the contaminants.

Back at U of T, Sleep and collaborators are working on understanding the chemistry and microbiology of the site so they can develop new and more effective methods for cleaning up contaminated sites.

“These spills can persist for decades if nothing is done to clean them up.”

As you type your emails, draft documents or write poems – any time your fingers press the keyboard – you could be charging the battery of your computer, or storing energy for later use.

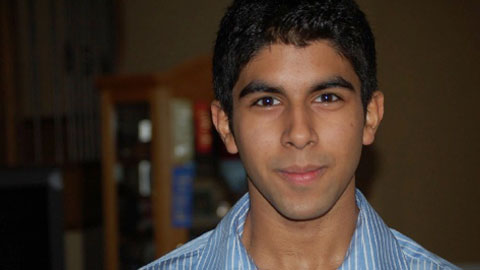

Deep Prasad (ECE), a first-year undergraduate and fellow of the Engineering faculty’s Entrepreneurship Hatchery, is designing novel ways to harness energy that could make keyboard energy generation possible – and change the way we charge our devices.

Prasad’s idea propelled him into the final round of voting for The Next Einstein contest, an initiative run by The Hebrew University in Jerusalem in conjunction with the Canadian Friends of the Hebrew University.

To become a top ten finalist, Prasad had to get the backing of a diverse panel of judges that included Nobel laureates, business and community leaders, and even the NBA’s Amar’e Stoudemire.

Albert Einstein himself was on the first board of governors at The Hebrew University, and the innovation competition now bearing his name seeks to support similarly world-changing ideas as those developed by the father of the theory of relativity.

“There are many online competitions today, but most of them are very, very limited,” CHFU President & CEO Rami Kleinmann told Shalom Toronto. “Everything is generally limited to a specific area or niche. We said that we want to encourage free and creative thinking.

“Albert Einstein, who came up with the theory of relativity, served as a clerk in the patent office of the Swiss mail service. He didn’t sit in some complex laboratory with all kinds of modern accessories.”

Prasad has already been singled out as one of the innovation stars of his cohort, as he and his brother continue to develop technology to reduce “vampire power” wasted by electrical appliances.

“Deep’s curiosity and eagerness to explore is very inspiring,” says Joseph Orozco, director of The Entrepreneurship Hatchery. “We are proud that The Hatchery factored into his decision to study at U of T.”

Prasad explained his newest concept to U of T News.

What is your (next) Einstein idea? My idea for the next Einstein competition is based on harnessing energy that is generated by typing. Basically, when you press down on anything with force, that energy can be absorbed and converted to electrical energy.

How did you come up with the concept? I keep something called an “Ideas Journal” where I write down a new idea everyday, and document how one could go about making it. This happened to be one of the ideas from my journal. I got the idea when I was walking up a staircase and realized how much gravitational energy we exert on to the stairs. On a smaller scale, I wanted to harness a similar type of energy, so I settled on the idea of keyboards that generate electricity when pressed on.

What kind of impact could this idea have? One of the greatest problems in today’s world is the way we harness energy, how we use it, and lack of energy in general. With over 300 million keyboards sold, even a fraction of this technology integrated in these keyboards could make a big difference. Imagine seeing a light bulb turn on as you type, or charging your own laptop without needing to plug it in to an outlet as often.

Furthermore, we could attach energy storing units that could be put away for later use, like batteries, or even shipped off to developing countries.

What are your goals if you win the contest? What’s next if you don’t win the contest? If I win this contest, I plan on putting away the first $3000-$4000 for strictly research purposes. My design requires something called Piezoelectric materials which actually help to convert different types of energy into electricity.

Once I finish my work at the U of T Hatchery, I will begin research into developing a viable product that can be distributed through a large channel, such as retail, or even KickStarter. The goal is to sell attachable keyboards first, and then hopefully partner up with laptop design companies.

If I don’t win this contest, I will just start putting money away little by little, so I can eventually build the idea on my own during my spare time.

How has U of T helped you develop as an engineer and social entrepreneur? The most relevant program at U of T that has helped me develop as both an engineer and an entrepreneur is the Hatchery program. It assigns a mentor and co-mentor to each team where they help the team to bring a product to market, while also teaching them important business skills. My mentor for the Hatchery is Professor Jonathan Rose, who is very helpful in both the technical realm of things, and entrepreneurial side too. He is mentoring my younger brother and me as we work to bring one of our inventions to market by the end of the summer.

What else is on the horizon for you? I look forward to seeing how this competition goes, and even more so what kind of an impact this idea will have. Generating electricity through typing is one thing, but imagine if we can expand this concept to greater mediums of harnessing energy, such as putting this technology under roads, sidewalks, staircases, etc.

Wondering why your hydro bill is so high this month? There is a chance your neighbours are offloading some of their consumption on to you, or even monitoring your usage to learn about your daily habits.

These are concerns that arise as we become more advanced in our regulation of energy through complex cyber networks – and the worries don’t stop there.

At a recent gathering of Canada’s energy and utilities regulators, delegates voiced their greatest fear: a coordinated physical and cyber-attack on critical infrastructure.

“It’s not a question of if but when we are going to have some sort of cyberattack on the grid,” said Philip Jones, former president of the national regulators’ association in the United States, according to The Globe and Mail.

Worries about cyberattacks mounted yet again a week later, when a U.S. district court indicted five Chinese military officials for hacking into the computer systems of Pittsburgh-area companies such as U.S. Steel, Westinghouse Electric, Alcoa and Allegheny Technologies.

“It’s a growing concern in Canada—we’re still evolving toward a highly connected cyber-enabled system,” said Professor Deepa Kundur (ECE), an expert on smart grid cybersecurity in The Edward S. Rogers Sr. Department of Electrical & Computer Engineering. “As we move into the future, we will start seeing greater dependence on information systems providing greater opportunities for cyber attackers to cause disturbances.”

But why would anyone want to hack into the Canadian grid? What could they learn from doing so?

Plenty, explained Professor Kundur. Whether they’re vandals, local criminals, or shadowy foreign agents, cyber-attackers could act on three possible motives:

Stealing energy

“Energy theft is a strong motivation for many. Someone could hack into smart meters in their neighbourhood to potentially shift their usage onto a neighbour’s,” said Kundur. Grow-ops could distribute their energy usage to neighbourhood premises to avoid drawing attention to their unusual consumption. “High energy usage is often an identifier of nefarious activity by local authorities. To hide, they will need to push their consumption onto another party.”

Obtaining real-time usage records

You can learn a lot about an individual’s daily routines and preferences by examining their energy consumption patterns. Modern meters sample data at high frequency, some as often as every 15 minutes, so any spies would clearly be able to tell when you leave the house and come home again, roughly how many people’s electricity is being used, and even which appliances you own—certain types and even brands of smart refrigerators, televisions, washers and dryers give off unique energy signatures.

Learning the system topology

“It’s always interesting to know the topology of a system, because it will help identify its strengths and its weaknesses,” said Kundur. Consider that a majority of the power used in the U.S. flows through a small fraction of the country’s transformers—disruption of those devices, if their location were known, would have a devastating effect on energy delivery.

You may also have a business reason for wanting to know the magnitude of a country’s investment in renewable energy, or the market penetration of smart meters—maybe you own a factory in China that manufactures those meters, or solar panels. And knowledge of a nation’s nuclear activity and capabilities is of high interest.

Are we ready for these attacks, and many more we haven’t thought of yet? We’re getting there, said Kundur. The ‘smarter’ we make the grid and our homes, the more opportunities we create for cracks to appear at the intersection of cyber and physical systems.

“That’s why my group’s looking at security vulnerabilities now, before it evolves,” she said. “It shouldn’t be an afterthought.”

Read more in the Globe and Mail.

When Angela Hu (TrackOne 1T8) was a little girl, she would often wonder what was happening on the inside of machines. Fueled by this curiosity, she went on to pursue math and science courses, achieving high grades that led her to U of T Engineering.

On the weekend of May 24-25, Hu travelled from Charlottetown, Prince Edward Island to the University of Toronto to join 95 other female students at the Girls Leadership in Engineering Experience, also known as GLEE.

Now in its third year, GLEE is hosted by the Faculty of Applied Science & Engineering to welcome female high school students to the engineering community. Currently, approximately one-quarter of the Faculty’s undergraduate students are female.

Over the course of the 30-hour event, attendees were immersed in the dynamic and passionate environment at U of T Engineering. They had the opportunity to meet future classmates, attend a career panel, take part in hands-on engineering workshops and stay overnight at Victoria College residence.

“GLEE has been awesome so far, especially the workshop where we were designing an artificial arm,” said Hu, who recently accepted her offer to TrackOne. “The group successfully did it and we were all so happy about this.”

Participants also attended a semi-formal dinner hosted by Dean Cristina Amon, who welcomed the aspiring engineers with a story about her very first failed experiment:

“When I was a young girl living in Uruguay, I was fascinated by how things worked. I thought there were people inside our radio singing and talking – so one day when my parents were away, I opened it and found there were no little people, but vacuum tubes and capacitors and other old-fashioned electronics. We might call this my first failed experiment!

“While most adults told me to stop disassembling devices, there was one teacher who encouraged me to tinker with things and take them apart. I feel so lucky that she started me on this journey that has taken me around the world, working with brilliant colleagues and amazing students like you.”

During dinner, Professor Angela Schoellig from the University of Toronto Institute for Aerospace Studies (UTIAS) gave a keynote address, sharing her research on robotics, controls and machine learning. She also demonstrated one of her flying robots.

Schoellig stressed the importance of focusing on subjects that inspire curiosity and fascination, rather than following the expectations of others. “About ten years ago, I was sitting where you are now,” she said. “And I had no idea what I was going to take. The only thing I really knew was that I loved math and the sciences. I learned about a program that would teach me to use math and the engineering sciences to solve real world problems, so I followed my instincts and enrolled. I never would have expected that, one day, I would be here, showing you flying robots. It’s impossible to predict the future, so the best thing you can do is to choose something that you are really passionate about.”

Another incoming student Tatiana Joseph (MechE 1T8), also a strong believer in letting your interests guide you to a career, laughed about her special relationship with math and science. “Me and physics, we go out together,” said Joseph, a Montréal resident whose trip to GLEE brought her to Toronto for the first time. “I’m someone who wants to create things – things that can be useful to other people – and I found that engineering would allow me to do that. There are so many possibilities, it’s exciting.”