London-based Women in Mining (UK), a non-profit association aimed at promoting the achievements and position of women in all levels of the global mining industry, has named Samantha Espley (GeoE 8T8) as one of their top 100 inspirational women in mining worldwide.

Espley is part of a Canadian contingent of 12 honourees in the 100 Global Inspirational Women in Mining Project, a list designed to promote the significant impact of women in the traditionally male-dominated industry.

“WIM (UK) has collaborated with WIM groups all over the world in order to reflect a broad cross-section of global industry talent in The 100 Global Inspirational Women in Mining project,” said Amanda Van Dyke, chair of WIM (UK). “From engineers and geologists, to finance professionals and investors, each woman has been selected because of the lasting impact she makes on those around her as a positive role model and her contribution to the industry.”

Currently the General Manager (Mine and Mills Technical Services) at Vale – Sudbury Operations, Espley’s lengthy curriculum vitae reflects this impact.

She was a founding member of Women in Science and Engineering, a local group dedicated to promoting women in the broad science and technology academic disciplines, in 1998 during her graduate work. One year later, she received the Governor General’s Gold Medal, an award that honours the doctoral student with the highest standing at each university.

From 2003 to 2008, she chaired the science committee and held a position on the Board of Directors at Sudbury’s Science North, one of the leading science educational centres in Canada. Espley is currently the Co-chair of the Underground Working Group, Global Mining Standards and Guidelines Committee.

She has been recognized for her hard work, too, having received the International Women’s Week Award in 2004, the Canadian Institute of Mining, Metallurgy and Petroleum (CIM) Distinguished Service Medal in 2009, and the Trailblazer Award from Women in Mining Canada in 2013.

Espley was also recently honoured by the University of Toronto Engineering Alumni Association, receiving the 2013 2T2 Mid-Career Achievement Award. This award recognizes a graduate who has earned respect within the profession and broader community, attained significant achievement and exhibits promise of further contributions.

“Samantha is truly a trailblazer,” said Professor Brent Sleep, Chair of the Department of Civil Engineering. “Her work to promote women in the Canadian and global mining industries is inspiring to our community of future engineers. We congratulate her on this recognition and are honoured to count her as one of our alumni.”

U of T Engineering nurtures a culture of entrepreneurship in its students – a strategy that pays off over and over again. It’s no surprise then that 10 of 40 students from across North America selected for The Next 36 program are once again from U of T’s Faculty of Applied Science & Engineering.

This increasingly popular program is designed to train Canada’s next generation of innovators and business leaders. Competition this year was tough, with close to 1,000 applicants.

Those who are selected are given the opportunity to develop their business ideas and put them into action with help from Canadian business leaders, mentorship and lectures from world-class faculty over a nine-month period, according to Jon French, spokesperson for The Next 36. This entrepreneurship-immersion program also provides those selected with up to $95,000 in seed investment for new ventures.

“It is very rewarding from the work we are doing that the spirit of entrepreneurship is coming alive. Seeing 10 of our students among The Next 36 shows the message of innovation and an understanding of business is coming through,” said Joseph Orozco, Executive Director, Entrepreneurship – The Entrepreneurship Hatchery and Adjunct Professor of the Centre for Management of Technology and Entrepreneurship (CMTE). He noted that one of The Next 36 students has applied to the Hatchery program, which offers similar services, and he hopes to see more.

“I personally believe we all have an entrepreneurial seed inside of us. What we do here is allow that seed to flourish. It’s not always about creating your own business but being able to work in any environment, any company. These students are going to be better members of society,” he said.

That the spirit is alive is evidenced by the fact five of U of T’s Next 36 students are either enrolled in, or have completed Engineering entrepreneurship courses. And impressively, nine of those selected from the U of T came from Engineering’s enriched program, Engineering Science.

“There is a renewed emphasis on design and innovation in the Faculty of Applied Science & Engineering, and this is contributing to a culture of entrepreneurship in our students. Needless to say, I am extremely pleased with the performance of our students in this year’s The Next 36 competition and confident that they will make the most of this outstanding opportunity,” said Professor Mark Kortschot (ChemE), Chair, Division of Engineering Science, and himself an experienced entrepreneur.

Timothy Ahong (EngSci 1T3 + PEY) and James Schuback (EngSci 1T3) are two who made it onto The Next 36 list. They are on a team developing a wearable motion sensor which provides feedback on athletic technique and motion for a variety of sports. The device compares a person’s motion, whether it’s a tennis or golf swing, or other motions, to that of the pros.

“The Next 36 is an amazing opportunity, and I still can’t believe I’m doing this. Entrepreneurship is the path I’ve chosen after graduation, and I plan to pursue this or a related project,” said Schuback.

The U of T Engineering students in The Next 36 will be building their startups along with their co-founders (small teams applied) and mentors. The ideas presented by students included: a motorized blimp for filming events, a fashion consulting platform, leveraging GPS and Bluetooth to help parents monitor young children, and wearable technology for athletes.

Projects may change from the initial idea over the course of the program as Venture Day in mid-August 2014 gets closer – the program’s annual Capstone Event where ventures are showcased to investors and business leaders from across North America. It is also when the students will officially graduate from The Next 36 program.

The Next 36 was started as a way to address Canada’s shortage of high-impact entrepreneurs. The organization provides a resource-rich program to a select group of promising undergraduates, and was founded by a small group of entrepreneurs, business leaders and academics, a number of whom are U of T Engineering alumni.

This year’s student selection include: Timothy Ahong (EngSci 1T3 + PEY), Amir-Hossein Karimi (EngSci 1T4), Shums Kassam (EngSci 1T5), Vivek Kesarwani (EngSci 1T3 + PEY), Drew MacNeil (EngSci 1T5), Tejas Mehta (EngSci 1T4 + PEY), James Schuback (EngSci 1T3), Jonathan Yam (EngSci 1T3), Victor Zhang (ElecE 1T3) and Cheng Zhao (EngSci 1T2 + PEY).

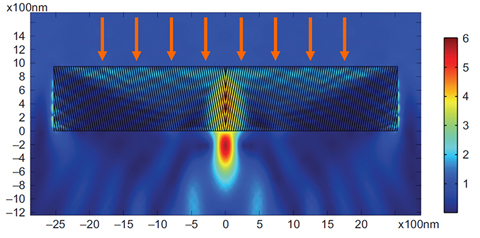

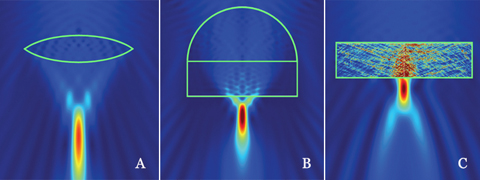

Researchers in The Edward S. Rogers Sr. Department of Electrical & Computer Engineering have designed a new way to focus light over extremely short distances, technology with big applications in photovoltaics and optical imaging.

Picture a typical lens, shaped like half a grapefruit lying face-down. Light rays pass through the lens and focus some distance away from its surface. This distance is the focal length. In order to achieve short focal length and focus light relatively close to the lens’s bottom surface, the lens needs to be very thick, and therefore heavy. To gather the maximum amount of energy from the sun and minimize cost, solar panels concentrate light through lenses onto single cells for absorption. Such current solar panel designs are relatively bulky and heavy to accommodate these thick lenses.

But what if you could concentrate light directly on the underside of a solar panel, and make it thin and light at the same time? Metamaterials hold the solution.

Professor George Eleftheriades (ECE) and PhD student Mohammad Memarian (ECE) have demonstrated a way to stitch together a class of light-channeling metamaterials such that light is funneled to focus much closer to the exit surface of the flat lens.

“It works like a sink full of water, with all the light flowing into the drain in the middle,” said Eleftheriades. “Nobody’s done this before, and the reviews were very enthusiastic.”

“What’s attractive about this is its broad impact — everyone can see why it’s important and how we can use it,” said Memarian. “I’m hoping to follow this up, and I think it’s valuable to take this further and apply it either to solar cells or to other ideas that we have.”

This work was published in the Nov. 22, 2013 issue of the online Nature journal Light: Science & Applications, and since its publication has been the most-downloaded paper from the journal. This work received support from the Natural Sciences and Engineering Research Council of Canada and Defence Research and Development Canada.

When you win a competition by time measured in milliseconds, it’s like being in the Olympics. That’s what happened to Shang Wang (ECE 1T7) at the first Connect6 game competition, organized as part of Engineering’s APS105 computer programming course.

Connect6 is a cross between the popular Chinese board game Go, and tic-tac-toe. The board measures 19 squares by 19 squares, and the object is to get six game pieces in a row – either up and down or on a diagonal.

But the game Wang played – held in the atrium of the Bahen Centre for Information Technology on Nov. 29 – came with a twist. The ‘players’ were actually computer programs that first-year Engineering students wrote as part of an assignment. Students’ programs were pitted against each other, and the games were projected onto a screen. If a game was a draw, the program that took the least amount of time to play, won.

The Connect6 competition attracted close to 150 students. The event added a whole new dimension to making an assignment exciting, according to Professor Jason Anderson (ECE) who came up with the idea.

“It was the first time we’ve given first-year students an open-ended programming problem, and the first time we’ve created a project-related event like this. The solutions students produced were remarkable and shows you can encourage excellence in ways that are fun,” he said.

Prior to the event, all students’ programs were played against each other (more than 400 first-year U of T Engineering students take this introductory programming course), until there were eight finalists. The winning game was a draw, but Wang’s program beat that of his classmate, Rongzhen Cui (ECE 1T7) by 11 milliseconds. Cui came in second, overall.

“I was surprised I was selected for the finals,” Wang said. He had never played board games before, and relied on help from a classmate to work out game strategies to improve the odds of winning.

Jake Kutkevicius (TrackOne) came in third. All three students described the project as fun, and enjoyed the challenges of the assignment. They were each awarded a Google Nexus 7 Tablet.

According to Professor Jonathan Rose (ECE), it was the first time instructors tried using a game as a way of exposing first-year students to the type of problem-solving conundrums they’ll encounter later in life. “We were impressed with the quality of the programs the students wrote,” he said.

A new algorithm designed at the University of Toronto has the power to profoundly change the way we find photos among the billions on social media sites such as Facebook and Flickr. This month, the United States Patent and Trademark Office will issue a patent on this technology.

Developed by Parham Aarabi, a professor in The Edward S. Rogers Sr. Department of Electrical & Computer Engineering, and his former Master’s student Ron Appel (ECE MASc 0T8), the search tool uses tag locations to quantify relationships between individuals, even those not tagged in any given photo.

Imagine you and your mother are pictured together, building a sandcastle at the beach. You’re both tagged in the photo quite close together. In the next photo, you and your father are eating watermelon. You’re both tagged. Because of your close ‘tagging’ relationship with both your mother in the first picture and your father in the second, the algorithm can determine that a relationship exists between those two and quantify how strong it may be.

In a third photo, you fly a kite with both parents, but only your mother is tagged. Given the strength of your ‘tagging’ relationship with your parents, when you search for photos of your father the algorithm can return the untagged photo because of the very high likelihood he’s pictured.

“Two things are happening: we understand relationships, and we can search images better,” says Professor Aarabi.

The nimble algorithm, called relational social image search, achieves high reliability without using computationally intensive object- or facial-recognition software.

“If you want to search a trillion photos, normally that takes at least a trillion operations. It’s based on the number of photos you have,” says Aarabi. “Facebook has almost half a trillion photos, but a billion users—it’s almost a 500 order of magnitude difference. Our algorithm is simply based on the number of tags, not on the number of photos, which makes it more efficient to search than standard approaches.”

Work on this project began in 2005 in Professor Aarabi’s Mobile Applications Lab, Canada’s first lab space for mobile application development.

Currently the algorithm’s interface is primarily for research, but Aarabi aims to see it incorporated on the back-end of large image databases or social networks. “I envision the interface would be exactly like you use Facebook search—for users, nothing would change. They would just get better results,” says Aarabi.

While testing the algorithm, Aarabi and Appel discovered an unforeseen application: a new way to generate maps. They tagged a few photographs of buildings around the University of Toronto and ran them through the system with a bunch of untagged campus photos. “The result we got was of almost a pseudo-map of the campus from all these photos we had taken, which was very interesting,” says Aarabi.

This work received support from the Natural Science and Engineering Research Council of Canada. It will be presented at the IEEE International Symposium on Multimedia Dec. 10, 2013.

Most people don’t go looking for problems, but U of T Engineers seem to be an exception to that rule. In fact, Ted Sargent, Vice-Dean, Research for the Faculty of Applied Science & Engineering, stood in front of a room of about 200 industry partners and faculty on Nov. 21 and asked for more problems. Speaking at an industry partners reception at The Faculty Club, he then went even farther. He thanked representatives from companies ranging from telecom and software to biotech and sustainable energy for presenting some of their most difficult challenges to faculty and students. “People from industry bring to us something that is incredibly valuable, which is problems that are important. They are societally relevant, they are important to health and to the environment,” said Sargent, who is also a Professor in The Edward S. Rogers Sr. Department of Electrical & Computer Engineering (ECE) and holds the Canada Research Chair in Nanotechnology. “When you come to us with problems, we often end up making fundamental discoveries because we go off in directions we wouldn’t have otherwise,” he added. Meanwhile, Ken Stevens, Manager of Collaborative Research at Dupont Canada, stressed that his company’s research partnerships with U of T Engineering have been a two-way street.

“We value collaboration to keep our pipeline of innovation full,” he said. “I’ve been impressed by the multidisciplinary aspect of research here. This is where major things happen. It’s a wonderful institution and one of the leading research-intensive universities in the world.” While Stevens spoke of Dupont Canada’s long-term relationship with U of T Engineering, others such as April Khademi, Senior Scientist at digital pathology company PathCore, were looking to establish new partnerships.

PathCore is a two-year-old company that develops software to help pathologists make better and faster diagnoses. “We want to give researchers access to our software so they can help us validate and refine it,” said Khademi. IBM contract advisor Perry Fuller says his company’s technology incubation lab has repeatedly called on U of T engineers to help with the kind of refinement Khademi is looking for. “We look at products we develop in the lab and ask if they have problems that bright minds at universities could work on. It not only gives faculty a good project, but it allows us to apply their solutions to our products,” said Fuller.