A University of Toronto (U of T) team led by Engineering Professor Yu-Ling Cheng, Director of the Centre for Global Engineering, has garnered third place and $40,000 (USD) for their design of a toilet for the developing world.

The design was a response to the Bill & Melinda Gates Foundation’s Reinvent the Toilet Challenge, which seeks to develop a waterless, hygienic toilet that is safe and affordable for people in the developing world that doesn’t have to be connected to a sewer.

U of T was one of eight universities from around the world to receive the initial phase one funding of almost $400,000 each. That investment allowed the teams to test their conceptual design. Those designs were showcased at the Gates Foundation’s Seattle headquarters, where the Reinvent the Toilet Fair was being held.

The U of T solution is novel in its simplicity. It uses a sand filter and UV-ray disinfecting chamber to process liquid waste and a smolder chamber, similar to a charcoal barbeque, to incinerate solid waste that has been flattened and dried in a roller/belt assembly. The result is a toilet that is sustainable, easy to use and that processes waste while protecting the community from contamination. A video fully explaining the design is below.

“A lot of science has gone into our work, but we have been careful in our design to ensure that any of the equipment and processes we use can be easily repaired and managed in a remote community by people with limited resources and training,” explained Professor Cheng. “The result is a toilet design that will not only address the pressing challenges associated with poor sanitation, but is sustainable and usable by some of the poorest people in the world.”

Traditional toilets, which rely on running water, an extensive sewer network and an expensive processing system, are currently failing to the meet the needs of 2.5-billion people around the world according to the Gates Foundation. An estimated 1.5-million children die each year due to diarrhea caused by poor sanitation.

At a ceremony held on August 15 at the Fair, Bill Gates announced the U of T team has won third place. Also recognized were teams from the California Institute of Technology (first place; $100,000), Loughborough University in the United Kingdom (second place; $60,000 USD), with a special prize presented to Eawag (Swiss Federal Institute of Aquatic Science and Technology) and EOOS ($40,000 USD).

“The efforts of the University of Toronto team, who is tackling one of the world’s pressing health challenges, have been tremendous. I congratulate the entire team for this richly deserved award, and thank Professor Yu-Ling Cheng who has led the development of this novel toilet system, combining ingenious designs and research with social and geographic constraints, to improve sanitation and global health,” said Professor Cristina Amon, Dean of the Faculty of Applied Science & Engineering.

In addition to Professor Cheng, the U of T team included Engineering Professors Mark Kortschot, Elizabeth Edwards, Yuri Lawryshyn and Levente Diosady, and research associates/graduate students Zachary Fishman, Tiffany Jung, Samuel Melamed and Meagan Webb. Their efforts were supported by partners at the University of Edinburgh, Western University, OCAD University and technical experts in Bangladesh.

Professor Shaker A. Meguid (MIE) has received the 2012 EUR ASEM Robert Hooke Award from the European Society for Experimental Mechanics for his outstanding contributions in the field of experimental mechanics applied to mechanical design and materials.

Shaker Meguid’s innovative research in engineering mechanics and design is recognized worldwide. His research over the past 30 years has contributed significantly to nano-micro-meso mechanics, electro-thermo-mechanically coupled problems, and fracture mechanics of nanoreinforced interfaces. Professor Meguid is the Editor-in-Chief of the International Journal of Mechanics and Materials in Design and has authored more than 430 papers and two books. He is a Fellow of the Engineering Institute of Canada, the American Society of Mechanical Engineers and the Institution of Mechanical Engineers of Great Britain.

“I am pleased Professor Shaker Meguid has received international recognition from his colleagues in the experimental mechanics community,” said Jean Zu, Chair of the Department of Mechanical & Industrial Engineering (MIE). “Professor Meguid is an exemplary leader in his field and on behalf of the faculty, I congratulate him on this highly deserved honour.”

EURASEM is a European non-profit scientific and engineering society whose general purpose is to provide a Europe-wide forum for the discussion of all aspects related to Experimental Mechanics. Since 1959, EURASEM has organized the International Conference on Experimental Mechanics (ICEM).

Professor Meguid received his award on July 26, 2012, at ICEM 15 in Porto, Portugal.

Imagine a machine that makes layered, substantial patches of engineered tissue – tissue that could be used as grafts for burn victims or vascular patches. If this sounds like science fiction, researchers at the University of Toronto say it’s a growing possibility.

A team led by two U of T Engineering professors has invented a new device that may allow for the uniform, large-scale engineering of tissue. Associate Professor Axel Guenther of the Department of Mechanical & Industrial Engineering, cross-appointed to the Institute of Biomaterials & Biomedical Engineering (IBBME), and Associate Professor Milica Radisic, core professor at IBBME and the Department of Chemical Engineering & Applied Chemistry, developed the device with a team included graduate students Lian Leng, Boyang Zhang, and Arianna McAllister.

“There’s a lot of interest in soft materials, particularly biomaterials,” explained Professor Guenther, “but until now no one has demonstrated a simple and scalable one-step process to go from microns to centimeters.”

The invention, presented in a cover article for the journal Advanced Materials this month, is currently being commercialized by MaRS Innovations in collaboration with the Innovations and Partnerships Office (IPO) of the University of Toronto, through which Professors Radisic and Guenther’s labs have filed two patents on the device.

But how exactly does a machine grow a large patch of functional tissue?

Scientists manipulate biomaterials into the micro-device through several channels. The biomaterials are then mixed, causing a chemical reaction that forms a “mosaic hydrogel” – a sheet-like substance compatible with the growth of cells into living tissues, into which different types of cells can be seeded in very precise and controlled placements.

The current methods for tissue engineering relies on scaffolding, in which cells are seeded onto an artificial structure capable of supporting three-dimensional tissue formation. However, that method provides little control over where the cells settle. The U of T method allows cells planted onto the mosaic hydrogel sheets to be precisely incorporated into the mosaic hydrogel sheet just at the time it’s being created – generating the perfect conditions for cells to grow.

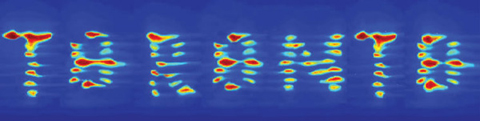

The placement of the cells is so precise, in fact, that scientists can spell words (such as “Toronto,” shown above) and can accurately mimic the natural placement of cells in living tissues. By collecting these sheets around a drum, the machine is able to collect layers of cells in thicknesses made to measure: in essence, three dimensional, functional tissues.

In tissue engineering, cell placement is everything: something that the new invention delivers. “The cells are able to stretch and connect with each other, which is very important for ultimately obtaining functional tissues,” Guenther states.

The resulting tissues are remarkably stable, explained Leng, lead author on the project and a third-year PhD Candidate in Mechanical & Industrial Engineering. “In this case, when we put the cells in the right places, we create cellular organization quite naturally.”

So what’s the next step?

“With the help of biomaterials experts and clinical collaborators, my laboratory is currently pursuing different applications of the technology – different tissues,” said Professor Guenther. The technology may provide the means to create three-dimensional cell cultures for the development of therapeutic drugs, for instance. “But one of my dreams is to one day engineer a vascularized leaf – perhaps a maple leaf,” he joked.

Currently, the two U of T labs are also collaborating with a burn unit at Sunnybrook Hospital. “At some point [the machine] could allow dermal [skin] grafts to be prepared that perhaps will be less expensive and more efficient,” stated Professor Guenther.

Learn more about it in the winter 2013 issue of U of T Magazine.

Researchers from the University of Toronto (U of T) and King Abdullah University of Science and Technology (KAUST) have made a breakthrough in the development of colloidal quantum dot (CQD) films, leading to the most efficient CQD solar cell ever. Their work is featured in a letter published in Nature Nanotechnology.

The researchers, led by U of T Engineering Professor Ted Sargent who also serves as the Faculty’s Vice-Dean, Research, created a solar cell out of inexpensive materials that was certified at a world-record 7 per cent efficiency.

“Previously, quantum dot solar cells have been limited by the large internal surface areas of the nanoparticles in the film, which made extracting electricity difficult,” said Dr. Susanna Thon, a lead co-author of the paper. “Our breakthrough was to use a combination of organic and inorganic chemistry to completely cover all of the exposed surfaces.”

Quantum dots are semiconductors only a few nanometres in size and can be used to harvest electricity from the entire solar spectrum – including both visible and invisible wavelengths. Unlike current slow and expensive semiconductor growth techniques, CQD films can be created quickly and at low cost, similar to paint or ink. This research paves the way for solar cells that can be fabricated on flexible substrates in the same way newspapers are rapidly printed in mass quantities.

The U of T cell represents a 37 per cent increase in efficiency over the previous certified record. In order to improve efficiency, the researchers needed a way to both reduce the number of ‘traps’ for electrons associated with poor surface quality while simultaneously ensuring their films were very dense to absorb as much light as possible. The solution was a so-called ‘hybrid passivation’ scheme.

“By introducing small chlorine atoms immediately after synthesizing the dots, we’re able to patch the previously unreachable nooks and crannies that lead to electron traps,” explained doctoral student and lead co-author Alex Ip. “We follow that by using short organic linkers to bind quantum dots in the film closer together.”

Work led by Professor Aram Amassian of KAUST showed that the organic ligand exchange was necessary to achieve the densest film.

“The KAUST group used state-of-the-art synchrotron methods with sub-nanometre resolution to discern the structure of the films and prove that the hybrid passivation method led to the densest films with the closest-packed nanoparticles,” stated Professor Amassian.

The advance opens up many avenues for further research and improvement of device efficiencies, which could contribute to a bright future with reliable, low-cost solar energy.

According to Professor Sargent, “Our world urgently needs innovative, cost-effective ways to convert the sun’s abundant energy into usable electricity. This work shows that the abundant materials interfaces inside colloidal quantum dots can be mastered in a robust manner, proving that low-cost and steadily improving efficiencies can be combined.”

Throughout summer, students walking around the Engineering Complex at U of T may look younger than usual. They’re not engineering students just yet – some won’t be for a handful of years – though the summer programs offered at U of T Engineering are helping them get there.

Wrapping up on July 27 is the Da Vinci Engineering Enrichment Program (DEEP) Summer Academy. For 10 years, DEEP has brought together more than 9,000 high school students from around the world to U of T, all of them sharing a passion to become engineers.

“We’ve gone from being just a day program where we saw a couple hundred students to being a residence program where we’re seeing over a thousand students from around the world,” said Dawn Britton, Associate Director of U of T Engineering’s Outreach Office.

Here, they get hands-on experience through design courses and are taught by the best and brightest graduate students and alumni on a vast number of engineering topics, from stem cells to robotics to solar energy.

Students this year also got to meet U of T Engineering’s famed Blue Sky Solar Racing Team, where they were amazed at the sight of racing cars, Cerulean and Azure. “I’m totally joining this if I end up coming here!” said one student. “What do you think about building a 12-wheeled solar car?” asked another.

“These are really bright students,” said Seyed Ali Nasseri (AeroE MASc candidate), who is teaching three courses, including the design course, Design, Build, Fly! Nasseri sees the program as not only inspiring for his students, but for him as well. “For the instructors, this is an opportunity to experiment with different ways of teaching. It’s also really fun.”

As DEEP comes to a close for another summer, outreach programs Jr. DEEP and ENGage are set to begin August 6.

Jr. DEEP invites students from grades 5 to 8 to explore engineering disciplines through a number of courses taught by undergraduates. ENGage, now in its third year, also seeks to nurture fifth to eight graders’ interest in engineering and science, while promoting academic and social growth and development for black youth.

Dimpho Radebe (IndE 1T4), ENGage coordinator and instructor, sees the ever-growing program – it was only offered to grades 7 and 8 in previous years – as invaluable.

“It’s the only program of its kind in Canada,” she said. “Having students excited about science, technology, engineering and math at a younger age increases the likelihood that they will continue to be excited about it as they grow older.”

That was the case for ENGage co-founder and fellow instructor Mikhail Burke (MSE 1T2). “It was thanks to U of T programs that I decided at 12 years old that I wanted to do science and engineering as a profession and that I wanted to study at U of T.”

He added, “Many youths who share my ethnic background don’t have the same resources or opportunities as I had. ENGage creates an avenue to stimulate more young black minds and has an opportunity to assist in the production of more successful U of T alumni such as myself.”

To learn more about U of T Engineering’s outreach programs, visit:outreach.engineering.utoronto.ca/home.htm

It’s the Da Vinci Engineering Enrichment Program Summer Academy but everyone calls it DEEP – and for the 10th straight year, it’s welcoming ambitious high school students from across Canada and around the world to U of T.

Running for four weeks in July, the camp offers teens the chance to go deeper into their high school curriculum – giving them the opportunity to learn fundamental math and science skills typically mastered by first- and second-year university students.

The past decade has seen the Academy undergo tremendous transformation.

“We’ve gone from being just a day program where we saw a couple hundred students to being a residence program where we’re seeing over a thousand students from around the world,” said Dawn Britton, Associate Director of the Faculty of Applied Science & Engineering’s Outreach Office.

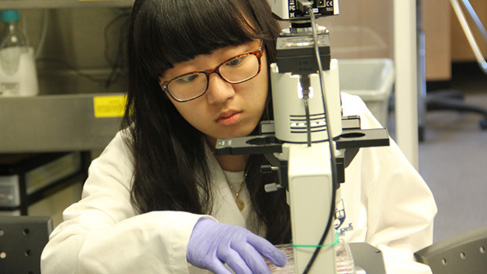

The Academy’s sessions, targeting everything from design to enzyme digestion to fluorescent imaging, are designed and led by U of T Engineering students. Graduate students take areas of their research and pare the subject down to foundational skills that help prepare students for future studies, while undergraduate students gain invaluable experience as camp counsellors who assist the running of the courses.

“We have really incredible instructors, phenomenal students,” said Britton.

Esther Lau, a co-instructor on a course on stem cells, obtained her MASc from IBBME in Biomedical Engineering and is now in her second year of medical school. She has seen DEEP’s impact on students ripple out over the years.

“The first year they started running the program I remember being a student of DEEP, and what I was able to get out of it. As a grad student I’m able to come full circle and be in a teaching role.”

It’s an opportunity worth leaving home for – even if it means travelling across the world.

“It takes 12 hours to get from Korea to here,” said Chae Kyung Lim, a grade 11 student who made that journey to be a part of the DEEP experience. “But I love the very high level [of teaching].”

The hands-on laboratory experience and cool equipment is a major draw for many of the camp’s participants, as well. Getting to manipulate the state-of-the-art microscopes is exciting, as are exercises such as how to change the “food” for cell cultures inside a massive bio-safety cabinet that continuously circulates air in the newly renovated, top-of-the-line IBBME undergraduate teaching lab.