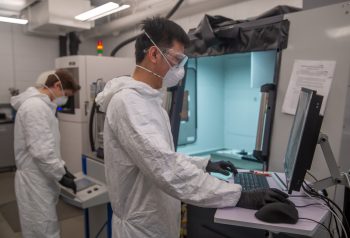

Researchers at the Open Centre for the Characterization of Advanced Materials (OCCAM) are working with the conservation team at the Royal Ontario Museum (ROM) to help preserve links to the past, ensuring important historical artifacts can be studied and shared with generations to come.

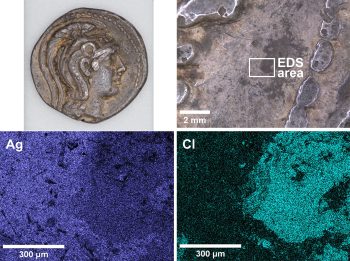

Maria Stanko (MSE 2T2 + PEY, MSE PhD candidate) and her collaborators are studying the surfaces of two corroded Greek coins from the Hellenistic period, dating back to 300-115 BCE, using OCCAM’s instrumentation. By understanding what is happening to these priceless relics, the team will be equipped to advise researchers and conservators on how to best conserve and store these artifacts safely.

“We are so lucky to have this amazing resource available to us. It’s not just about having access to state-of-the-art technology and tools, this is an excellent team to work with,” says Laura Lipcsei, a senior conservator at the museum. “They are sharing important information, and we couldn’t do our work without them.”

The coins are subjects of study for the ROMkomma project, a collaboration funded by the Social Sciences and Humanities Research Council and led by Professors Kate Cooper (UTSC Historical and Cultural Studies), a research associate at the ROM, and Ben Akrigg (Classics). The project aims to catalogue and publish data on the ROM’s extensive collection of ancient Greek coins, which contains more than 2,000 coins. This investigation, which will make the ROM’s Greek coin collection accessible online, could reveal important insights on early minting practices and how early economies were developed.

“Environmental degradation is normal with coins that are thousands of years old,” says Stanko. “On a few of these coins, we’re likely seeing corrosion caused by elements like chlorine and bromine.

“These corrosive products are harder than the coin itself. We risk damaging the artifacts and removing the fine surface detailing if we try mechanical cleaning methods.”

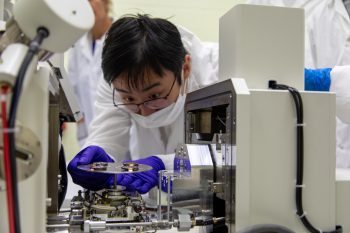

She and her colleagues, including Dian (Jack) Yu (MSE 2T1, MSE PhD candidate) and Dr. Michel Haché (MSE PhD 2T3), an MSE postdoctoral fellow, along with Stanko’s PhD co-supervisor Professor Jane Howe (MSE, ChemE), developed a strategy to examine the coins with a scanning electron microscope paired with energy-dispersive X-ray spectroscopy (SEM-EDS).

“Once we know more about the chemical composition on the surfaces of these coins, we can advise ROM conservators on non-destructive treatment strategies and storage solutions,” Stanko says.

The project has proven to be challenging. Since EDS works by exciting the electrons on the surface of a sample to emit X-ray signatures, the team needed to fix the position of the coins — without the use of clamps or guides that might cause damage — for the signals to hit the detector in just the right way.

This type of analysis works best for smooth and flat objects, so the team spent hours examining the uneven faces of these coins under an optical microscope to identify specific areas where the samples could be imaged and analyzed.

The ROMkomma project is just one of many currently underway at the centre right now.

“OCCAM is the infrastructure supporting research across U of T and beyond,” says Howe, the newly appointed co-director of OCCAM, who played a leading role in installing the equipment at the centre.

“Many branches of science and engineering rely on understanding the structure of materials at atomic and nano scales, whether it’s related to designing catalysts for green energy, developing new biomolecules in medicine or enhancing microchips in our smartphones. Our work benefits every researcher tackling today’s grand challenges.”

Howe is looking forward to an upcoming collaboration with Hitachi High-Tech, involving a low-cost structural analysis tool that could significantly bring down the cost of characterizing the structure of new materials.

She also identifies the centre’s focus on teaching as one of its core strengths.

“At OCCAM, we don’t restrict access to our world-class instrumentation to post-doctoral fellows and senior researchers. Undergraduate and graduate student get hands-on experience and are encouraged to come to us with projects.”

In fact, the coin imaging and analysis project Stanko brought to OCCAM’s attention was part of a class assignment for the Analytical Electron Microscopy course she was taking with Howe. Stanko and her classmates have greatly benefited from focused training and mentorship from Sal Boccia, an engineering technologist at the centre.

Meanwhile, Professor Doug Perovic (MSE), expert in materials characterization and forensic engineering, is excited by the centre’s role in the development of solar fuels. Working in collaboration with U of T Department of Chemistry professor Geoffrey Ozin’s lab, Perovic is interested in designing new materials that will absorb greenhouse gases and sunlight and convert them into useful fuels.

“Central to all of this work is understanding what we are actually making, the reactions occurring and the issues that might exist,” says Perovic. “We have all the tools we need to accomplish this at OCCAM — we give researchers a closer look at the core of the process and how the system is functioning.”

He’s confident the centre will play a significant role in advanced manufacturing, including supporting the development of self-driving labs, like those to be realized at U of T’s Acceleration Consortium.

“As we move to an automated way of making materials, we are still going to need characterization expertise and tools to qualify what we’re seeing,” says Perovic. “OCCAM will be here to support and provide those capabilities.”