A retired smartphone languishing in a drawer may seem nearly worthless, but from a material point of view, it’s a gold mine. Professor Gisele Azimi (ChemE, MSE) and her team are developing new methods for recovering strategic materials — including rare earth elements — from disused electronics and other forms of waste.

“Strategic materials are those which are in high demand, but also subject to supply risk,” says Azimi. This doesn’t necessarily mean that they are hard to find — the process of extracting them from raw ore may be costly, generate harmful byproducts, or be subject to political instability in the regions where they are found.

Rare earth elements, such as neodymium and dysprosium, are used in magnets and batteries, and growing demand for both consumer electronics and electric vehicles is causing prices to rise faster than new mines can be developed to supply them. Now various industries are looking at non-traditional sources for these materials.

Azimi and her team are working with Nutrien, a major global producer of fertilizer, to develop techniques for extracting rare earth elements from an industrial byproduct called phosphogypsum. They have also partnered with Rio Tinto Alcan to harvest rare earth elements from a byproduct of the aluminum industry known as ‘red mud.’

“Both of these had been traditionally thought of as waste streams,” says Azimi. “While the percentage of rare earths in them is low, the tonnage available is high enough to make the economics attractive.”

The team is also looking at post-consumer waste, such as the nickel-metal-hydride batteries used in electric vehicles, which Azimi says can contain up to 30 per cent (by weight) rare earth elements. She is also investigating the enormous magnets used in wind turbines. “A single wind turbine has 600 kilograms of neodymium in it,” says Azimi. “That’s a very rich source.”

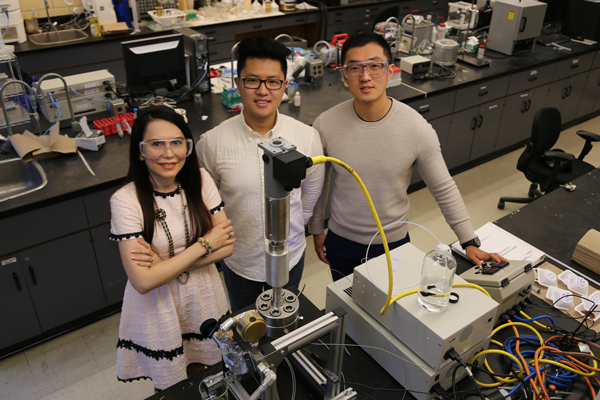

Current recycling techniques require either harsh acids or bases or high heat, making the extraction process energy-intensive. In contrast, Azimi and her team are using carbon dioxide that has been heated and pressurized until it becomes what is known as a supercritical fluid.

In their process, ground-up elements of old batteries are treated with the supercritical fluid, which attracts the rare earth elements and enables them to be separated from the rest of the material. This technique is already common in the food industry, where it’s used to decaffeinate coffee beans, but Azimi is among the first to apply it to metals extraction.

In a recent paper, Azimi and her team showed that supercritical fluid extraction can recover up to 90 per cent of the rare earth elements contained in a nickel-metal-hydride battery. Future work will focus on growing this process from the lab to the industrial scale.

“The breakthrough ideas are the ones that have not been tried, but if they are enabled, they can completely change how an industry works,” says Azimi. “The risk is higher, but the day that I see that it is working is a very bright day for me.”