U of T Engineering professor’s startup receives federal funding to manufacture solar-energy-control windows

3E Nano Inc., co-founded by Professor Nazir Kherani and based on his research in photovoltaics and thermal systems, has received $5 million in funding from Sustainable Development Technology Canada

This alumni startup is taking organic LED displays to the next level

Newest innovation from OTI Lumionics enables integration of displays with different types of sensors and cameras, allowing device makers to create notch-free screens

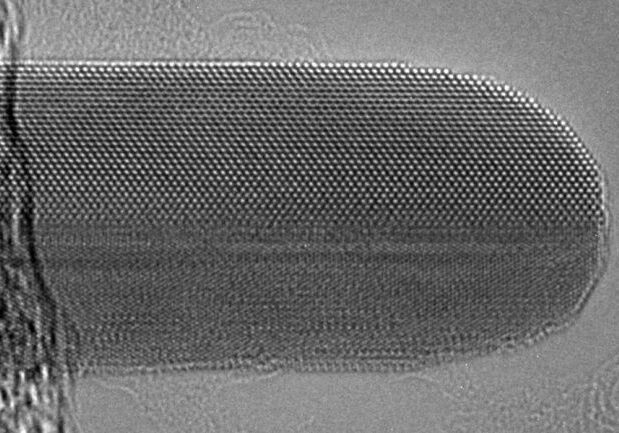

New insight into how nanoparticles form could advance technologies from solar cells to medical tests

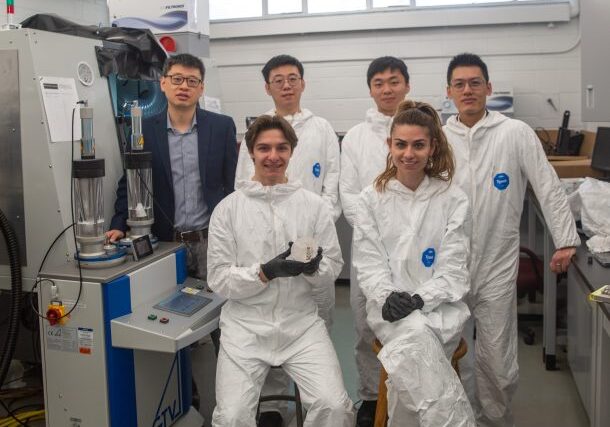

Researchers from U of T Engineering have discovered a distinctive mode of growth that could be leveraged to customize nanoparticles for a variety of applications

This new, more sustainable method for recycling lithium-ion batteries could help meet electric vehicle demand

U of T Engineering researchers are using supercritical carbon dioxide to recover lithium, cobalt, nickel and manganese from end-of-life lithium-ion batteries

U of T Engineering and Ford partnership introduces new sustainable material into the automotive industry

Professor Mohini Sain’s team worked with Ford Motors Canada to create a Carbon Fibre-Composite 5.0L Engine Timing Cover

Graphene-like 2D material leverages quantum effects to achieve ultra-low friction

Magnetene could have useful applications as a lubricant in implantable devices or other micro-electro-mechanical systems