A U of T Engineering student team has earned the top spot in the International Small Wind Turbine Contest (ISWTC) with a smart, sustainable design that includes components made of recycled pop bottles and plant-fibre composites.

This is the second time the team has won the contest following their debut performance in 2022. Their first-place finish saw them outcompete seven other teams from countries including Denmark, Poland, the Netherlands and Spain.

“We didn’t really expect to win best overall, but we thought we had a decent chance at winning for the most sustainable design,” says Dhara Patel (Year 2 ElecE), incoming co-president of the UTWind team.

“When we found out we didn’t win that award, we were pretty devastated, but it was a complete shock to then find out that we won the whole competition — our mouths just hung open for a while!”

Patel was still a high school student when the UTWind team won their first competition in 2022. She says that reading about their success was one of the things that inspired her to study at U of T Engineering.

The team she eventually came to co-lead currently includes more than 50 students from across U of T Engineering, as well as some from the Faculty of Arts & Science. They are divided into five sub-teams: aerodynamics, mechanical and manufacturing, control systems, power systems and sustainability.

The ISWTC — hosted annually by Hanze University of Applied Sciences in Groningen, Netherlands — challenges teams from around the world to design and build a small-scale wind turbine that could be deployed to generate power in sub-Saharan Africa.

The area covered by the spinning blades is limited to less than 1.6 square metres, and the top of the upper blade must stay below 3 metres in height. Teams are evaluated on the overall energy yield of their turbine, the sustainability of their design, the quality of their construction and the presentation they give to the judges.

“This year, we made improvements to the pitch system, and we also implemented more sustainable materials,” says Justin Ding (Year 2 MechE), the incoming co-lead of the mechanical and manufacturing team.

“For example, we used plant-based flax fibre composites to make the blades, which makes them lighter. The nose cone was made from recycled polyethylene terephthalate, or PET plastic, which is more sustainable than using new material.”

Elena Sloan (Year 3 MechE), the other co-lead of the mechanical and manufacturing team, explains how it was done.

“We gathered plastic pop bottles from around campus, including the student-run Hard Hat Café,” she says.

“We then cut these bottles into strips and extruded them through a heated nozzle to make 1.75 mm diameter filament, which we could use in our 3D printer.”

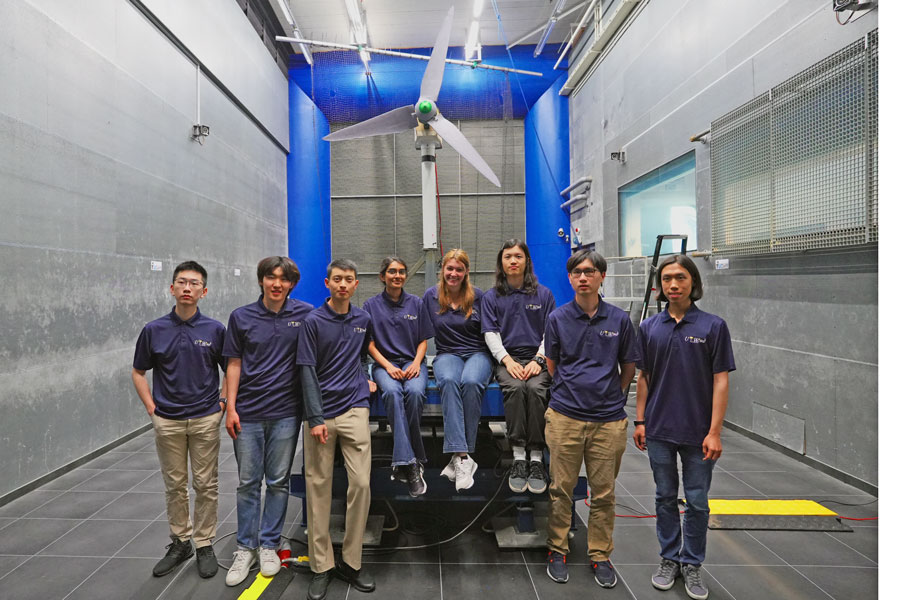

Once the turbine was complete, it was disassembled and packed into four bags of checked luggage for the flight to the Netherlands. The team’s first stop was Delft, where their turbine underwent performance testing in a wind tunnel at Delft University of Technology’s Open Jet Facility.

The testing showed that the team was able to harvest about 36% of the available energy at a wind speed of 8.5 metres per second, a solid, but not outstanding result.

From there, the team members took a three-hour train ride across the country to Groningen, where they gave their technical presentation, followed by the awards ceremony.

“It was kind of surreal — at first I thought I misheard the word Toronto,” says Robert Zhao, an undergraduate student in the Department of Physics and the other incoming co-president of UTWind.

“I started thinking ‘how did we win?’ But it just goes to show that it’s not just about who had the most sustainable design, or who generated the most power. It’s about consistent strong performance across all the categories.”

The team is energized by their win, and they have big plans for next year.

“We’ve learned so many lessons, before, during and after the contest,” says Zhao.

“But our competitors have also learned those lessons, and there are more of them than ever before. We need to improve our winning design, making it more robust and more mature to better defend our title.”

Patel says the team would also like to try building a vertical-axis turbine, in addition to their standard horizontal-axis version.

“Vertical-axis turbines look really cool, and they are structurally simpler and have a lower profile than horizontal-axis ones,” she says.

“Only one other team has tried that. We’d like to take on that challenge, and ultimately put one on our own campus buildings to generate clean wind power.”