New CREATE grant powers training and innovation in thermal management to enhance performance of electric vehicles and battery systems

Multidisciplinary team led by Alumni Distinguished Professor Cristina Amon (MIE) includes 10 professors and 21 industry, academia, and government collaborators from across Canada and international

Dean Emerita Cristina Amon named U of T University Professor

Appointments to the University’s highest academic rank are limited to two percent of its tenured faculty

U of T Engineering students collaborate across time zones through ‘Global Classrooms’ initiative

The team is working with students at Covenant University in Nigeria to design a low-cost biogas generator for rural communities in the African country

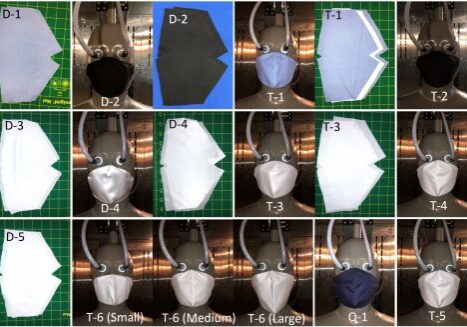

Are safer masks more uncomfortable? New U of T Engineering study offers answers

Professor Kevin Golovin (MIE) analyzed 12 different face masks to investigate connections between discomfort and protection.